Then and Now: A Look at How the Garbage Truck Has Evolved

Today, refuse fleets seek technologies that will enhance their operations, particularly when it comes to safety, maintenance and recruiting the next generation of workers.

Refuse trucks have come a long way from the days of the horse-drawn garbage collection cart and the dump truck bodies of the late 1800s to the trucks of today—equipped with cameras, telematics, onboard diagnostics and automated arms to make waste collection safer and more efficient than ever before. But even with the highly sophisticated trucks on the streets today, refuse fleets across the country continue to struggle with safety and a growing labor shortage.

Waste haulers today are looking for technologies that will enhance, but not overwhelm, their operations, particularly when it comes to safety, maintenance and attracting and retaining a younger workforce. Here’s a look back at how equipment has evolved since the inception of the garbage truck, as well as how refuse fleets have leveraged advancements in technology over the years.

A Look Back in Time

Autocar was founded at the birth of the American automotive industry and is one of the oldest motor vehicle manufacturers in the western hemisphere. In 1899, the company advertised its first motor truck for sale, and by 1911, the company focused solely on building trucks to fill a need within the market.

According to Adam Burck, head of marketing for Autocar Trucks, the company’s founder was a tech entrepreneur, who started building internal combustion engines around 1890. In 1897, he founded The Autocar Company.

“The very first garbage trucks were not really differentiated from a typical dump truck,” explains Burck. “The waste hauler picked up trash and threw it in the back. People realized pretty quickly that a typical dump body was not very well suited for waste because a lot of waste in those days was ash and it would leak out.”

So, Autocar began building specialized dump bodies that were sealed on the sides. However, as trucks got bigger and taller, it became more difficult to throw waste in. Plus, the waste would spill out. This led to the ever-more sophisticated waste bodies and a whole series of cabover trucks that were suited for in-town use, notes Burck.

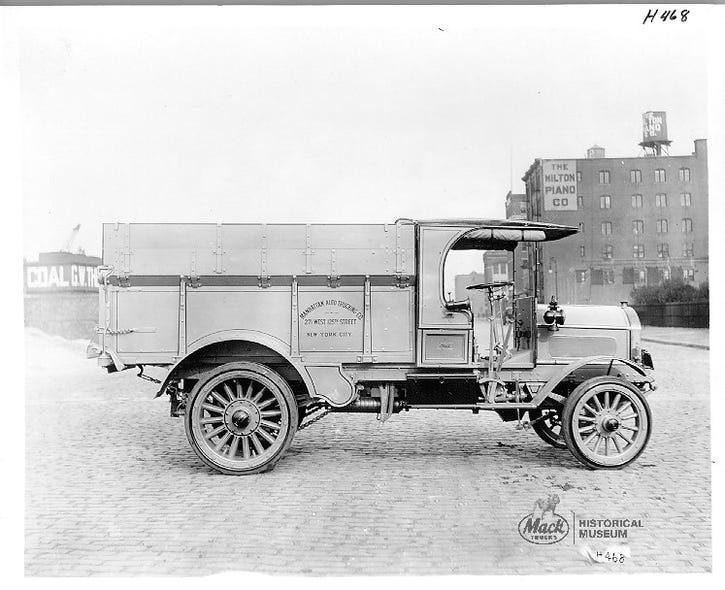

For Mack Trucks, the earliest verified product intended for refuse use was a 1908 Manhattan Seat-Over-Engine chassis with a dump body mounted by Mack Bros. Motor Car Co. According to Curtis Dorwart, Mack refuse product manager, it is likely that the Mack brothers built refuse collection vehicles even earlier than that.

The earliest Mack product specifically built for the refuse industry was the Mack Senior, circa 1915. This model featured fold down sides on the dump body for ease of hand loading, as well as chain guards to prevent loose materials from getting tied up into the drive mechanism.

More than a decade later, in the 1930s, fleets started experimenting with different kinds of waste hauling bodies. New York City awarded Autocar and Heil a joint contract to build a fleet of hundreds of innovative self-loading escalator body trucks. These trucks were safer, more efficient and had a 25 percent payload advantage over hand-loaded trucks, Burck points out.

Labrie Enviroquip Group is another company that has had a presence in the refuse market for more than 100 years. Labrie offers three platforms: The Labrie platform, which is the traditional mixed city known for recycling and automated equipment. The front loader, which was originally a Western Canadian and West Coast front loader that has now evolved into a national product. And the Leach Rear Loader, which has been around for more than a century.

According to Skip Berg, business development manager of automated collection for Labrie Enviroquip Group, the company is known for its drop frame side loader, which takes a traditional truck chassis, cuts the frame rails, adds a bend that lowers the frame behind the cab and ramps it up back toward the rear axle. In that recess is the hopper in the side loader.

“It was Labrie’s innovation that allowed that hopper to get deep enough to take roll-out carts for residential collection rather than hand toss the materials in,” says Berg. “That combination and then the addition of an automated arm on that same truck is what propelled automation in many parts of the country—in both Canada and the U.S. That was done back in the 1990s, and automation has come a long way since then.”

Don Ross, vice president of sales and marketing for New Way Trucks and the McLaughlin Family Companies, explains that New Way Trucks has been in business since 1968. But the company’s origins really started when Scranton Manufacturing, which has been manufacturing agricultural products including livestock gates and trailers since 1971, was operating in 1984 during the middle of a farm recession. In an effort to diversify, Scranton saw an ad for a garbage truck company in Des Moines, Iowa, that was for sale and ended up acquiring New Way Trucks.

At the time, New Way was building only two models: a small side loader and a small rear loader. In those earlier years, the company was building about 10 trucks annually.

“From that first truck, we immediately started making improvements, evolving into what we build today,” says New Way Trucks Founder John McLaughlin. “Jigs and fixtures were developed to replicate products in a standard fashion and to improve quality. We perfected hydraulic systems and tailgate assemblies and focused on improving compaction ratios.”

One of the biggest improvements New Way implemented was the curved side compaction body. This removed side bracing channels, eliminated large amounts of welding, reduced labor and resulted in weight savings, while improving compaction, explains Ross.

“Years ago, it would take a few strong men to man a truck and hoist steel trash cans and ash cans from the curbside into the back of what would be considered an oversized pickup truck by today’s standards,” Dorwart points out. “Today’s vehicles are designed to be operated by a single operator with many labor-saving and safety technologies built in that help make collection more efficient and safer.”

For decades, Freightliner Trucks has offered vehicle solutions for the waste industry. In this century, the company’s M2 106 conventional cab has been used by many manufacturers for both rear and side loader configurations. And in April 2018, the company introduced the new Freightliner EconicSD, a cabover engine model that was purpose-built for the daily rigors of refuse.

“Today’s waste collection trucks are more specifically focused on maximizing productivity, as well as keeping drivers safer and more comfortable,” says JP Davis, marketing manager of the vocational segment for Daimler Trucks North America. “Fleets are also more focused than ever on keeping the communities and neighborhoods where they work safer, and many trucks now include technologies that contribute to safer drivers and safer areas where the vehicles are operated.”

Advancements in Safety

The main driver for refuse fleets today is safety. And in an industry that is consistently ranked among the most dangerous professions, it’s no surprise that fleets are investing more and more in safety technologies.

One of the most popular technologies the industry has implemented today is the use of cameras—both around the truck and inside the cab. And camera technology, now offering a 360-degree bird’s-eye view around the truck, has evolved substantially.

“Safety doesn’t happen by accident; it has to be built into the truck,” says Burck. “It applies in every area of operation because the refuse industry, as we all know, is one of the most dangerous industries there is. So, we want to protect the driver. We focus a lot on getting in and out of the truck but also on protecting the driver in the case of accidents, even if they are not the driver’s fault.”

Burck notes that Autocar has implemented all-steel cabs and doors on its trucks designed to protect the driver in a side-impact situation. Plus, the company has enhanced visibility and ergonomics inside the cab to help with accident prevention.

Refuse fleets are also looking to telematics solutions to not only optimize routing but to improve safety as well. Data from telematics coming off the trucks can help fleet managers identify risky driving behaviors.

“These trucks can be set so that if there is abusive acceleration or braking, or unsafe maneuvering, cameras in the trucks can not only view what’s around the truck but view the driver compartment as well,” explains Berg. “If there is a G-force event or a sudden turn or brake, the camera captures a certain period of activity. The driver can be coached about that behavior or even in some cases exonerated. You’ll find issues where someone says the driver ran over their bicycle, when in actuality, the bicycle somehow got pushed in front of the truck and there was nothing the driver could do. Now, you have a photographic record of that.”

“When drivers say, ‘You’re trying to catch me doing something wrong.’ I always say, ‘I’m trying to catch you doing something right,’” he adds.

Another trend has been a shift toward a more integrated power unit and refuse body configuration. New Way is working with Autocar on the development of an integrated collection vehicle. Before integration, body upfitters like New Way were forced to modify the truck chassis in order to accommodate their bodies. With integration, a number of these modifications are done at the chassis manufacturer as original equipment, including prewiring truck cabs with body wiring harnesses, cameras and other options to eliminate rework and improve fit and finish. Truck frames are factory-finished with body mounting hardware in place.

“The basic items we take for granted today include standard LED lights, which have tremendous life expectancy compared to older technology, remote adjustable mirrors for safety and convenience, multi-camera systems, ergonomic operator controls, automatic body controls and, yes, even air conditioning,” notes Ross. “It wasn’t too many years ago that these were all options. The major technologies that fleets expect to see are high compaction rates, efficient, long-lasting, yet lightweight curved body shell designs, data acquisition tools and ergonomic operator controls.”

Ross says another trend is the number of customers interested in electric units. As a result, both rear load and automated side load configurations are under development now at New Way Trucks with BYD USA (Build your Dreams).

“With a finite onboard battery capacity, engineers have to consider every single action the body performs as an energy consumer,” he explains. “Every arm lift, every packing panel movement and every tailgate motion consumes an amount of stored electrical energy, and the task at hand is making sure the truck can complete its route while operating efficiently and without depleting its battery.”

At Labrie, automation has been driven in large part by the economic sense that it makes. Plus, the safety factor is undeniable.

“There is still an evolution going on in the automated world,” says Berg. “We are getting close to the point where the driver will simply stop at the right place, the camera on the truck will view the cart, artificial intelligence (AI) will identify that it’s the right cart and the arm will go out, grab the cart and put it back down.”

Inside the cab, original equipment manufacturers (OEMs) are installing automated operations, such as making the joysticks movable and the arm rests adjustable. So, the driver doesn’t manipulate a joystick; he or she simply holds down a button.

“When you’re servicing 1,500 homes a day with a joystick, you may not hurt your back jumping in and out of the truck, but you could end up with carpal tunnel syndrome from working the joystick unless you can move it around and make it a little more flexible,” explains Berg.

For Freightliner, safety technologies, such as the Detroit Assurance suite of safety systems, can help mitigate potential collisions and keep drivers, passengers, cars and pedestrians outside of the truck safe. Detroit Assurance comes standard in the Freightliner EconicSD and includes active brake assist, adaptive cruise control, lane departure detection and sideguard assist, which alerts the driver to objects on the side of the vehicle.

In addition to technologies like the Detroit Assurance, Freightliner’s EconicSD includes panoramic windshields, advanced mirror systems for expanded views and low seating positions for better visibility.

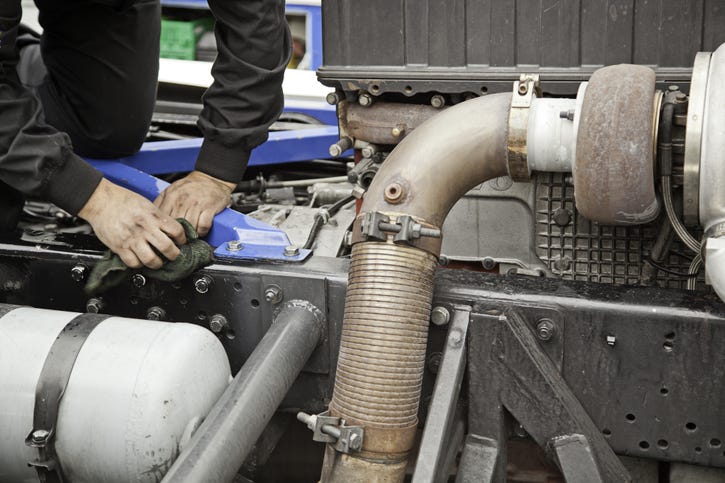

“There is very heavy use of electrical and electronic technologies not only in the trucks themselves but also in the body and the controls,” explains Dorwart. “CAN-based [control area network] controls and electronic logic have replaced cable controls and many of the pneumatic actuators of days gone by. These same technologies allow for safer vehicles because the digital controls can be programmed and set up to provide safety interlocks, auto-lifting capability, pack on the fly, etc.”

And because working in refuse can be a very stressful job, making the truck safe, efficient and comfortable goes a long way. That is why there has been such an industry-wide push to add safety technologies like camera systems, traction control, good visibility, ABS braking systems and so on to fleets. However, because these truck bodies are communicating with chassis more than they ever did, it can be difficult to find technicians who can work on the more advanced equipment.

Maintenance and the Growing Labor Shortage

Aside from safety, fuel consumption and maintenance costs are top priorities for refuse fleets today. And maintenance remains a top concern for fleets, particularly due to the industry-wide shortage of technicians.

Twenty years ago, trash trucks were not nearly as advanced as they are today, explains Tommy McGhee, director of vocational sales at Rush Enterprises. McGhee has been in the business for 24 years, and over the years, he has seen trash vehicles evolve from the more traditional roll-off, front load and rear load vehicles as the industry leans more toward automation.

“Trash trucks then were not as technical as they are today with all the additions, changes and greenhouse gas (GHG) sensors and aftertreatments—such as diesel particulate filters and all of the sensors you have to have to monitor GHGs coming out of the truck,” says McGhee. “Today, expert skills are required for advanced technologies on the truck.”

Chad Wellborne, general manager for RushCare, has been with Rush Enterprises for the last 12 years. He notes that the increasing complexity of these trucks has inspired the necessity for significant improvements in technology.

“In other words, being able to receive fault codes from these trucks prior to a truck arriving and when a problem occurs on the road,” explains Wellborne. “We are able to look at the data and determine what is wrong with that chassis as it occurs out on the road. We are able to dive into the health of that vehicle as it ran its route and see when that issue was arising to help determine what triggered that fault code. We are now able to see all that data, whereas, back in the day, when bringing a chassis in for repair, you might not be able to recreate that issue. Now, we’ve got a better opportunity to fix that truck correctly the first time and to reduce the number of fault codes and ongoing incidents in the future, which obviously reduces the overall expense and cost of ownership for the customer.”

Developments in technology have allowed Rush Enterprises to gain traction into the mobile business as well. Rush is able to send out technicians from its mobile fleet who can repair trucks while haulers run their routes.

“The goal is to repair those vehicles while they are not in service, so that the next morning when that driver is back in, the truck is ready to go,” adds Wellborne. “It virtually eliminates downtime in some of these scenarios.”

Although the role of the technician is evolving, McGhee notes there will still be a need for the more traditional technician who can assemble and dissemble components. However, one of the bigger challenges moving forward is recruiting, training and retaining those less experienced technicians.

“Everything went to computer-based software systems for diagnosing trucks. For one, you have to purchase that type of equipment, so you can properly diagnose the truck, and then for two, technicians have to be trained on it,” says McGhee. “That’s one of the reasons why I think you’re seeing more mobile services. Our technicians that we send out are usually a level four or five technician, which is a very highly skilled technician. They can work on an Allison Transmission, or a Cummins gas engine or a diesel engine. When we send those guys out, they have the software and the computers to be able to plug in and determine what the problem is with the truck.”

At Autocar, the company engineers its own aftertreatment layouts, conducts its own transmission programming on the main production line and works with component suppliers to obtain the latest technologies. When it comes to measuring uptime and total cost of ownership, Autocar utilizes a return on investment calculator to help customers see how much money that improved uptime will save them over the lifetime of the truck.

Autocar has implemented Cummins’ new X12 engine, which has a 6 percent improvement of fuel consumption over the engine it replaces, Burck notes. In addition, Autocar doubled the time between oil changes, reduced the amount of filters needed to be replaced and has worked to make it easier for customers to hire mechanics who may not have as much experience. The company has also invested in onboard diagnostics.

“We provide live, unlimited and free support from our Autocar Solutions team of expert techs,” says Burck. “They are available 24/7 to support our customers’ techs to help them solve problems themselves so they don’t have to send the truck out to a dealer to be repaired.”

Another challenge for truck technicians today is the ability to harness all the data coming from these more advanced trucks. There has been a growing move toward telematics solutions that help maintenance shops with diagnostics to keep trucks in operation.

“We’ve never had so much data and so much information before, so you find that our customers are in data saturation,” explains Wellborne. “Everyone is trying to figure out how to manage the data and organize it so it’s valuable and provides efficiencies. I think that is one of the biggest things we’ve gone through.”

“We are big in telematics and communicating with our customers because when a refuse customer takes a truck into one of our shops, he wants to know when he will get his truck back,” McGhee emphasizes. “Service guys are fixing the truck for the collections guys and they need to tell them when they will have their truck back, so they know when they can put the truck back on route. We used to do that with a spreadsheet, where we had a spreadsheet going back and forth. Now, we use our communication portal, RushCare Service Connect, in which a customer can log in and see the real-time status of the truck in the repair process.”

In the last 10 years or so, there has been a big push across the industry to transition to alternative fuels like compressed natural gas (CNG). That required new engine technologies, onboard storage designs for a fuel that requires greater space to produce an equivalent amount of energy and different safety controls and processes for fuel handling.

Ross explains that more of New Way’s customers are asking for automatic lubrication systems, narrow wheelbase and body options for better clearance in tight areas, and flexible options for multiple container lifting devices including bolt-on reeving packages for future planning.

“The nationwide CDL [commercial driver’s license] driver shortage is causing service delays and even disruptions in certain markets,” he stresses. “Fleet technicians are also in high demand. New Way Trucks is working hard to address both of these staffing issues. Our new under CDL automated collection vehicle is the perfect training ground for future CDL drivers because it utilizes the same arm and controls as our larger CDL side loader. Most new CDL drivers have no previous refuse experience and either come straight out of a CDL training school or from the long-haul trucking industry, both without prior refuse experience. Not only does the hauler have to train the new candidate on waste collection, routing, customer service, safety and all the other key elements of our business, but they also have to make sure they can safely operate the vehicle as designed. The other path for driver development is to tap existing utility type employees and help them obtain a CDL. They understand some of the key business elements but still have not done routed waste collection or operated the vehicle before. Identical controls and operation greatly reduce the learning curve for new CDL drivers.”

New Way is also incorporating fleet technician needs into its designs. The company has started producing its air-controlled Sidewinder model, something that had been previously discontinued and replaced with electronic controls.

“Many of our customers like the electronic controlled CANBus models, but some still want the original air-controlled units,” adds Ross. “And we have improved the CANBus units to help fleet technicians. Our CANBus units now have diagnostic features to help techs troubleshoot and repair issues quickly, should they arise.”

And because maintenance and upkeep are so costly, it’s important for companies to find the right balance and investment level for maintenance. Too little investment in preventive maintenance shortens the vehicle's life, and too much investment in maintenance could cause a fleet to waste money, explains Davis.

That’s why Freightliner—like other OEMs—ensured its EconicSD includes the Detroit DD8 engine, which has longer maintenance intervals. Freightliner also has an extensive dealer network that includes Elite Support-certified dealers. When it comes to best practices in maintenance moving forward, manufacturers across the industry are looking at ways to best meet the needs of their customers’ needs.

Conclusion

When it comes down to it, as long as people continue to generate trash, there will always be a need for advanced equipment and technology to make the job more efficient. Although technology has helped refuse fleets ramp up their safety efforts in the last decade or so, the industry still struggles to remove itself from the list of the most dangerous industries. Additionally, the looming labor shortage will continue to keep the industry on its toes, as it comes with developing new maintenance solutions for refuse fleets and recruiting and retaining a younger generation of workers.

About the Author(s)

You May Also Like