Designers, Students Get Creative for Final Cradle to Cradle Product Design Challenge

The winners created innovative products and furnishings that demonstrate the way good design can allow for abundance, endless reuse and pleasure.

More than 150 designers, sustainability professionals and students from 17 different countries recently competed in the sixth and final Cradle to Cradle Product Design Challenge, which was hosted by the Cradle to Cradle Products Innovation Institute in collaboration with 3D design software company Autodesk and lightweight metals technology, engineering and manufacturing company Arconic Foundation.

“Inspired by the methodology of the Cradle to Cradle Certified product standard, these designers have created innovative products and furnishings that demonstrate the way good design can allow for abundance, endless reuse and pleasure—eliminating the need to think in terms of waste or contamination while simultaneously propagating a Cradle to Cradle economy,” said Dr. Michael Braungart, co-founder of the Cradle to Cradle Products Innovation Institute, co-author of Cradle to Cradle and The Upcycle and founder and scientific CEO of EPEA Internationale Umweltforschung GmbH, in a statement.

For the challenge, participants re-envisioned and redesigned products for the circular economy in accordance with the Cradle to Cradle Certified product standard by using Cradle to Cradle Certified materials where possible. In addition, participants were required to complete a free two-hour online course called Designing Cradle to Cradle Certified Products for the Circular Economy, which was developed in collaboration with Autodesk and made possible by Arconic Foundation.

“As the trajectory of our global population, along with the volume of resources needed to sustain us, escalates, there has never been a more pivotal time to apply the Cradle to Cradle Certified product standard as a means of creating and verifying products for the growing circular economy,” said Institute Lewis Perkins, president of the Cradle to Cradle Products Innovation Institute, in a statement. “The designers who participated in this challenge—and the winning projects—reflect a keen awareness of the need to employ safe, healthy materials in the innovation of products that contribute positively to an economy driven by regenerative design.”

This challenge was the final competition in a series of six global challenges. For the series, more than 600 designers across 30 countries submitted more than 550 entries.

The judging panel for the final challenge included Chris Uecker, senior scientist, product design and development for Target; Dr. Debbie Mielewski , senior technical leader, materials sustainability for Ford Motor Company; Emma Fromberg , informal education programme manager for the Ellen MacArthur Foundation; Doug Brown, manager, business strategy, sustainability for BASF Corporation; Lewis Perkins, president of the Cradle to Cradle Products Innovation Institute; Nora Sophie Griefahn , co-founder and managing director for the Cradle to Cradle Association; Sachlene Singh, technology evangelist for Autodesk; Stephen Leonard, senior innovation leader, growth and insights for Arconic Foundation; Stuart Constantine, co-founder and publisher for Core77; and Warner Philips, cleantech entrepreneur and investor, founding board member for the Cradle to Cradle Products Innovation Institute.

Winners of the sixth and final Cradle to Cradle Product Design Challenge were each awarded a $2,000 cash prize. This year’s winners include:

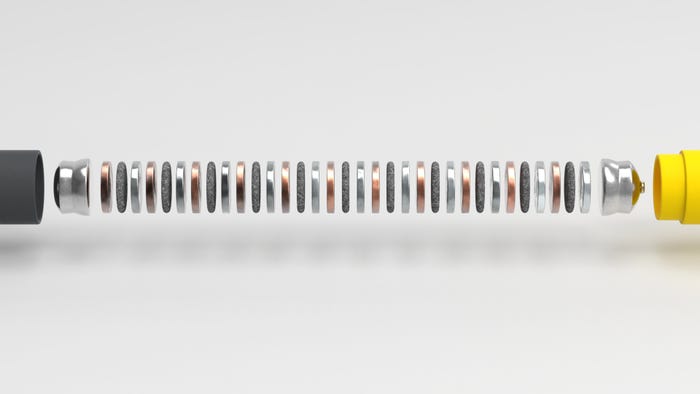

Volta

Best Overall Project

Koraldo Kajanku, San Francisco

Volta was selected for its innovative use of safe, healthy materials and design-for-disassembly approach in addressing the highly hazardous, global problem of disposable batteries. It employs non-toxic materials, such as Cradle to Cradle Certified Ingeo Biopolymer, in a battery that can be recharged in a bath of table salt and vinegar or remanufactured, composted and recycled. Volta’s fastener-free, pill-form design makes it easy to change parts, remove components from battery casing and disassemble for reuse and recovery.

House 4 House

Best Use of Cradle to Cradle Certified Materials

Agnieszka Filipowicz, Ania Pieranska & Otis Sloan Brittain, Copenhagen, Denmark

House 4 House was selected for its vision and design that focuses on engaging the next generation to learn circular design in buildings by doing. Its mission is to educate children about sustainability through house building kits, which in turn help to build a real house for every toy house sold. House 4 House challenges the typical pitched roof doll’s house design and allows children to explore their creative potential. Made with Cradle to Cradle Certified materials, including Accoya Wood, Alcoa Aluminum, Nispen Corrugated Packaging and Porotherm Bricks, each kit includes building supplies, characters, furniture and guides for building a miniature house. When the children decide they want to make a change, they can simply wash off the starch-based mortar and reuse it.

TO Stool

Best Use of Aluminum

Robert Shudram, Industrial Design Student, Carleton University, Ottawa, Canada

TO Stool blends form with function and was chosen for its elegant design and clever use of perforated aluminum. The stool, which is shipped flat and then folded into the final stool by the user, aims to adjust throwaway habits by encouraging and facilitating the diversion of used textiles into circular lifecycle streams. TO Stool is equipped with a removable bag located under the seat that serves as a storage area for textiles intended for donation or recycling. Once the bag is full, it can be easily transported to donation facilities. At the end of the stool’s useful life, the aluminum frame can easily be disassembled and infinitely recycled, and the renewable wood base can be repurposed or composted along with the accompanying textile bag.

Bench32

Best Use of Autodesk Fusion 360

Ralf Schneider, Assistant Professor – Industrial & Interaction Design, Syracuse University, New York

Inspired by the imperative weight reduction in airplane construction, Bench32 was chosen for its use of Fusion 360’s simulation capabilities to both ideate and render the design. The repetition of 32 wooden spars forms the seating surface, which is held together by 80 metal parts. Reusing parts multiple times and aligning the elements with ample negative space creates a lightweight appearance that results in a sturdy yet lightweight bench comprised of FSC-certified wood or Cradle to Cradle Certified Accoya wood.

About the Author(s)

You May Also Like