April 2020 Fire Report: How & Why Do Lithium-Ion Batteries Fail, Insight from the Jedi Master of Lithium Power!

April 2020 will go down as one of the longest months on record. I think we all can agree that this April dragged out for obvious reasons.

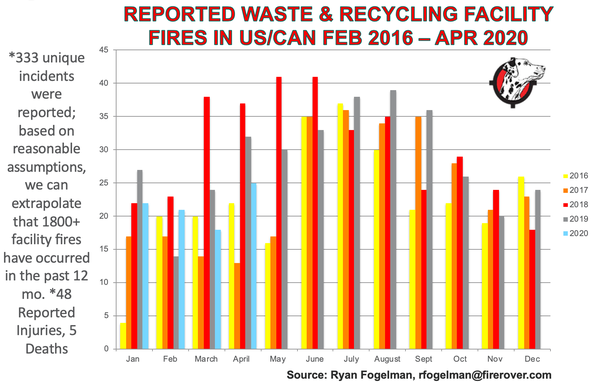

We experienced 25 reported fire incidents at waste and recycling facilities during the month. We experienced an unusual phenomenon that we have not seen in the past – specifically that the first week of April had only one reported fire incident. The final remaining 24 incidents occurred in the final 21 days of the month. This was more than one reported fire incident per day.

The main cause of these fires is lithium-ion batteries, which we delve into deeply with my special guest this month, Ronald Butler.

During the past twelve 12 months, the waste and recycling industry has experienced 333 reported facility fires in the U.S. and Canada. Additionally, we incurred 48 reported injuries and five deaths that can be directly or indirectly attributed to these fire incidents. Based on reasonable assumptions, we can extrapolate that 1,800 or more facility fires have occurred during that time, which based on the number of facilities reported by the Environmental Research & Education Foundation (EREF), is more than 40 percent of the Industry. I define “reported facility fires” as any fire reported by the media that occurs at a waste or recycling facility in the U.S. or Canada. Typically, the fires that are reported by the media are larger fires that require fire professionals to arrive on scene and where there are effects that the public can witness.

How Is COVID-19 Affecting Our Current Waste & Recycling Streams

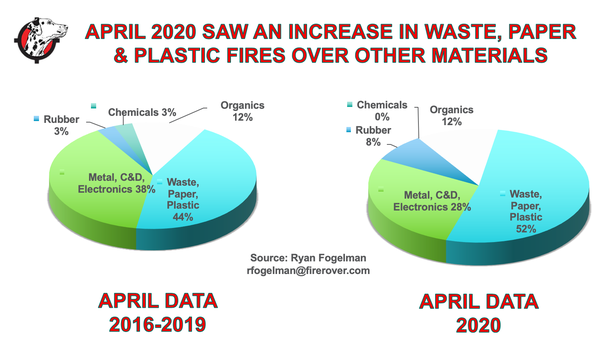

In March we saw an increase in the waste, paper and plastic fires versus trend. Waste, paper and plastic fires made up 56 percent of the fires in 2020 as compared to 45 percent of fire incidents in 2016, 2017, 2018 and 2019.

As one can imagine, it doesn’t typically make sense to break down data during a specific month, but some strange things are occurring. As mentioned above I only saw one fire incident in the first nine days of the month. This is the first time in four years we have experienced nine days with only one incident. I believe this is due to the tremendous changes we have experienced during the past 60 days because of the “quarantine effect” causing a transition from commercial to curbside waste volumes, the tremendous home and business clean-outs we are experiencing, (See here) the decrease in availability of recycling drop-off locations, school closures and more.

In addition, we continued the same trend of an increase in waste, paper and plastic fires at 52 percent as compared to 44 percent of 2016-2019 data.

How & Why Do Lithium-Ion Batteries Fail…and what we can do about it?

Insight from Ronald Butler, The Jedi Master of Lithium-ion Batteries!

During our stay-at-home orders, I have been holding weekly webinars Thursdays at noon ET to discuss the tremendous changes going on in our supply chain along with some special guest to provide insight into fire safety products. Ronald Butler, the CEO of E-cell Secure, was able to join us during episode #3 to discuss lithium power basics, supply chain and future implications of our global reliance on this medium. The full webinar is available on our Fire Rover page on YouTube, but here are a few of the highlights. (See here) Ronald will be joining me Thursday May 14th at noon EST to discuss “How To Properly Protect Your Operations From Lithium-Ion Battery Fires,” a taste of which is highlighted during our discussion below.

Ryan Fogelman: Tell us a bit about your background and why do they refer to you as the Jedi Master of Lithium Power.

Ronald Butler: I spent twenty-five 25 years as a fire professional for the city of Detroit Fire Department. I have spent the past eight years as CEO of ESSPI, now E-cell Secure, a consultancy focused on the entire lithium-ion power market and the risks of fire incidents across the entire life cycle. My firm works with the Fortune 500 companies, educational organizations, government organizations as well as safety organizations focused on developing innovative safety solutions and training modules. We also handle disaster planning centered around lithium technology. As for why they call me the Jedi Master of Lithium Power, “tell you…I must not!”

Fogelman: What is the difference between lithium batteries and lithium-ion batteries?

Butler: Lithium and lithium-ion batteries are different. Lithium batteries, or primary batteries, are single-use and incapable of recharge. They contain lithium metal, which is highly combustible. The real value in lithium lies in the fact that they deliver extremely high energy densities in small configurations.They are used where recharge isn’t necessary or feasible. Common applications include military use (warfighter applications), medical applications and certain consumer electronics, to name a few.

Lithium-ion batteries, or secondary batteries, are rechargeable and used worldwide. A lithium-ion battery finds applications that require recharge capability. Lithium-ion batteries provide high energy density, though lower than lithium primary, and can be recharged time after time. These batteries contain no free lithium metal but do contain lithium ions and highly flammable electrolytes. Common applications that incorporate li-ion technology include laptops, cell phones, electric vehicles, hospital equipment and energy storage systems, to name a few.

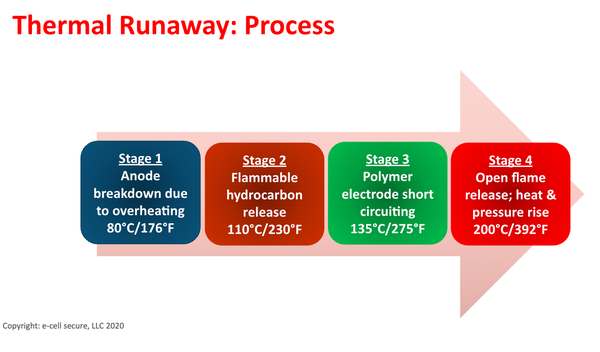

Fogelman: We constantly hear the term “thermal runaway.” What is it and what are the causes?

Butler: Lithium batteries are capable of spontaneous ignition and subsequent explosion from overheating. That may be caused by electrical shorting, rapid discharge, overcharging, manufacturers’ defect, poor design or mechanical damage, among many other causes. Overheating results in a process called thermal runaway, which is a reaction within the battery causing internal temperature and pressure to rise at a quicker rate then can be dissipated.

Once one battery cell goes into thermal runaway, it produces enough heat to cause adjacent battery cells to also go into thermal runaway. This produces a fire that repeatedly flares up as each battery cell in turn ruptures and releases its contents. The result is the release of flammable electrolyte from the battery and, in the case of disposable lithium batteries, the release of molten burning lithium. An enormous issue is that these fires can’t be treated like “normal” fires and require specific training, planning, storage and extinguishing interventions.

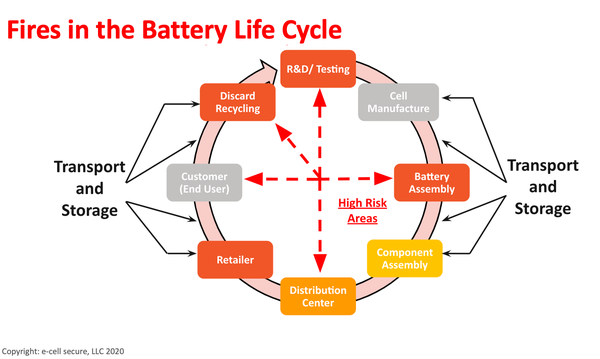

Fogelman: In the waste and recycling industry, we are usually the last ones in the supply chain to encounter these batteries. Can you give us an idea of the true scope of the power source?

Butler: Lithium-ion batteries are found in nearly every power requiring application. Airports see thousands of batteries go through their gates each day. Hospitals utilize battery power in more and more systems – from rechargeable gurneys to critical monitoring systems. Colleges and universities have them on campuses in huge amounts (i.e., laptops and smart devices). Lithium batteries are an integral part of everyday life now, with their use expected to expand further as demand grows and manufacturing costs plummet. Their impact is enormous now, but what will their impact be a few short years from now?

Fogelman: Can you address the fire threat of these batteries specifically?

Butler: As the use of lithium batteries grows, so will the fire threat in the entire battery lifecycle. Manufacturers, shippers, warehousing, distributors, retailers and some end-users will have to become more aware of the fire and safety hazards that accompany these powerful tools. Every stop of the battery supply chain is responsible for the safe storage and handling of the batteries.

Organizations that manufacture, ship and store lithium-ion batteries haven’t been immune to the fire incident. Thermal runaway events have contributed to a number of large-scale fires in facilities that contained stored lithium batteries. These fires are particularly high impact as they involve large volumes of batteries stored in configurations that encourage fire spread.

Fogelman: OK, we understand that lithium batteries are an issue. What is your advice for dealing with the issue?

Butler: Lithium battery fire risks can be managed effectively. Proper planning, risk assessment, storage methods and response protocols can go a long way in managing the fire risks of lithium batteries. The following areas should be addressed when developing strategies for managing battery fire risks

Storage/Transport Safety: There is inherent danger associated with the handling of batteries. In most cases, mechanical damage would probably rank as the highest risk factor for initiating a thermal runaway (fire/explosion) event. Improper handling can result in crush or puncture damage, possibly leading to the release of electrolyte material or short circuiting. These actions could result in thermal runaway and a resulting fire and/or explosion.

At minimum, an effective strategy for storing lithium batteries is to encourage suppression through cooling, isolation and containment (SCIC). A prime consideration in this approach is that batteries are housed in environments that feature fire suppression systems that extinguish through cooling. Suppressing a lithium-ion (secondary) battery is best accomplished by cooling the burning material; lithium primaries require separate and unique suppression methodologies.

Another consideration is that lithium batteries should be isolated from other battery chemistries and commodities (storage, transport, etc.). They should be stored (shipped) in environments that would effectively contain fires and toxic-burn byproducts. This is essential to health, safety and preservation of property. Close attention should be paid to isolating batteries from general facilities by developing external storage or “satellite” storage. Battery storage farms can allow for storage in sight with just-in-time shipment of batteries to the organization when needed.

Training: Companies that possess lithium batteries in high volumes should work with experts to develop training that seeks to mitigate the fire issues and ensure additional layers of safety. Training might address issues like battery awareness or include more detailed situational training such as battery fire behavior, emergency response procedures and fire suppression use (lithium battery focus). This type of training lends itself well to the preservation of life and property.

Standard Operating Procedures: Effective battery standard operating procedures (SOPs) will include processes that guide shipping and receiving, handling, daily use, storage and other functions involving the batteries. Proper SOPs will address every facet of the battery lifecycle. These procedures provide the basis for safe use and manipulation and the starting point for developing effective risk-management processes.

Emergency Response Procedures: In most instances, lithium battery fires shouldn’t necessarily be treated like common fires. The burn characteristics and toxic byproduct release components are simply different. An organization might determine their level of risk through proper assessment and create emergency response procedures based on sound response and battery handling data.

Fogelman: Is lithium here to stay, and what do you think we need to do to keep our businesses safe?

Butler: I am, and always will be, a huge advocate for lithium and lithium-ion batteries. They fill massive societal needs. This will grow in the future. I do, however, realize the importance of mitigating the risk presented by this technology. If industry begins to partner with the fire service, the insurance industry, providers and industry advocacy to limit risk on the front end, we will create a powerful safety cohort; one that can provide a pathway forward for continued, safe growth.

I mentioned in one of your presentations a few of these partners that I think help support this mission. Organizations like the Rechargeable Battery Association (PRBA) and the Responsible Battery Coalition on the industry advocacy side, the University of Texas (Austin) and Michigan Technological University on the battery safety research side, and the National Fire Protection Association (NFPA) and Society of Automotive Engineers (SAE) on the fire service/industry safety and protection side, are a few examples.

Another area for improvement, certainly as it related to the recycling industry, is in political advocacy. In this space, Sens. Angus King (Maine) and Debbie Stabenow (Michigan) have shown great leadership in developing reasonable laws that shape safety in the battery recycling industry. It is important that we begin to nurture these cooperative environments in an effort to be proactive and pre-empt current and future issues rather than reacting to them.

Please join Ronald and I Thursday May 14th at noon EST. In a follow-up to the first webinar on the Basics of Lithium-Ion Battery, titled “How to Properly Protect Your Operations from Lithium-Ion Battery Fires!” in which Ronald will take a deep dive into focused developing employee training, SOPs and emergency response procedures for your organization.

Additionally, I will be sharing the up-to-date results for reported fires in waste and recycling facilities during the webinar as well. You can sign up here.

Ryan Fogelman, JD/MBA, is vice president of strategic partnerships for Fire Rover. Fogelman focuses on bringing innovative safety solutions to market, market. Two of his solutions have won the distinguished Edison Innovation Award for Industrial Safety and Consumer Products. He has been compiling and publishing the “The Reported Waste & Recycling Facility Fire In The US/CAN” since February 2016, the “Waste & Recycling Facility Fire Annual Report” and speaks regularly on the topic of the scope of fire problems facing the waste and recycling industries, detection solutions, proper fire planning and early-stage fire risk mitigation.

Additionally, Fogelman is on the NFPA Technical Committee for Hazardous Materials. (See here)

About the Author(s)

You May Also Like