What’s Inside Dell’s Sustainability Playbook?

The multinational tech company worth over $102 billion in Fiscal Year 2023 has pledged to source more than half of its product content from recycled, renewable, or reduced carbon emissions material, and 100 percent of its packaging from recycled or renewable material by 2030.

The world discards about 54 million tons of electronics every year, placing these commodities at the top of the list of fastest-growing waste streams—and that number will likely reach 74 million tons by 2030, according to the United Nations Global E-Waste Monitor.

Policies are evolving to try and curb the flow while consumers expect to hold onto their computers longer. Electronics manufacturers are responding by doubling down to improve the circularity of their products, including majors like Dell.

The multinational tech company worth over $102 billion in Fiscal Year 2023 has pledged to source more than half of its product content from recycled, renewable, or reduced carbon emissions material, and 100 percent of its packaging from recycled or renewable material by 2030. Other projects are underway in answer to demand for electronics that are easier to repair and for more takeback options.

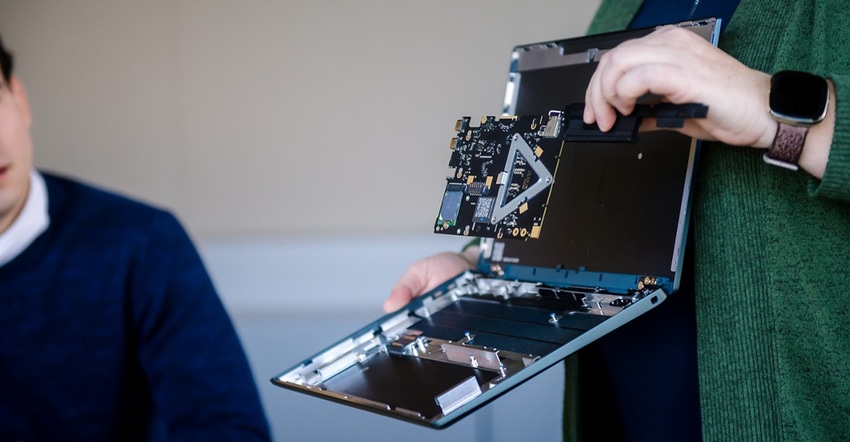

The work has entailed ferreting out new partners with industrial waste streams for feedstock. It includes vetting biobased materials, some which are already dropped into Dell’s fastest-moving products. And other efforts center around developing modular designs so e-cyclers can quickly disassemble devices and access components.

In Fiscal Year 2023 more than 86 million pounds of sustainable materials went into Dell technology. So far 75 percent recycled aluminum is incorporated into Notebooks and displays. Between 10 and 16 percent recycled steel goes into various components, and about 50 percent recycled copper lives on in power cables.

In 2024 Dell is introducing recycled cobalt into laptop batteries and more products with recycled steel, and soon you will see an expanded line of modular components, such as a serviceable display panel, says Katie Green, sustainability product strategist, Client Solutions, Dell Technologies.

Green ranks bioplastics among the computer manufacturers’ most noteworthy materials innovations. These renewables are sourced from castor oil that’s mixed with rubber for bottom bumpers and a bioplastic called tall oil, a byproduct of paper manufacturers’ pulping process. Dell also sources reclaimed carbon fiber from the aerospace industry.

Combining postconsumer recycled plastic, bioplastics, and carbon fiber has enabled a 71 percent recycled and renewable blend to be incorporated into laptops. And durability testing has shown that mixing in bioplastics yields the benefit of strengthening the recycled postconsumer plastic feedstock, Green says.

To better understand what e-cyclers struggle with Dell met with them and asked what would make their jobs more doable.

What these supply chain partners want Green says is consolidated components and improved access to key parts, namely the battery, keyboard, and display. Now Dell uses less adhesives and screws and is testing standard tools and fasteners as well as snap-fits or uniform screws. E-cyclers and refurbishers can also tap into an artificial intelligence-assisted tool guide for directions on repair, as well as instructions for retiring and recycling devices.

Takeback programs are another focus area.

On the consumer side Dell takes back any brand and pays for shipping. And through partnerships with over 2,000 Goodwill locations about 620 million pounds of material have been recovered for recycling.

Commercial customers tap into asset recovery services in 36 countries. Dell picks up the products; does data sanitization; manages resale; and provides customers data on the devices’ journey from collection to final disposition.

That second life goes a long way.

“New laptops typically have a three- to four-year lifespan. But they could last another three or four years if they are refurbished,” Green says.

In Fiscal Year 2023, Dell recovered 16.5 percent of products sold, representing a 4.4 percent increase from 2022.

Partnerships are a must for advancing circularity, says Kelly McCarthy, circular economy strategist, Sustainability & ESG, Dell Technologies.

“No one can do this alone. It’s important to work together on industrywide initiatives by engaging across the supply chain to identify best practices,” she says.

Among key collaborations is the Circular Electronics Partnership, where the private sector, government, and international organizations are working on an industry roadmap for circular electronics.

NextWave Plastics is a consortium of multinational technology and consumer brands, founded by nonprofit Lonely Whale and Dell, to create a commercial scale supply chain for ocean-bound plastic. With help from informal workers who collect plastic from overseas coastal communities, members have diverted 20,479 metric tons.

The genesis was a pilot between Dell and Lonely Whale to capture 16,000 pounds of plastic otherwise headed to the ocean and incorporate it into a Dell laptop package. A year later, NextWave was born.

“Dell’s team was instrumental in bringing the right decision makers to the table, including Michael Dell himself, to not only rethink Dell’s supply chain, but to reach across industries and invite other leaders to join them,” says Emy Kane, managing director at Lonely Whale.

“At Lonely Whale we use the phrase ‘radical collaboration.’ This is a perfect example of that thinking in action,” she says of the initial hookup between her small nonprofit and the manufacturing giant, and the work of the coalition that has followed.

As Dell reaches for its 2030 targets, the team looks ahead to 2050, with the goal to achieve zero greenhouse gas emissions across Scopes 1-3.

“This requires global cooperation across many aspects of our business and our broader value chain, a science-based approach, and consistently meeting our time-bound interim goals,” McCarthy says.

“We can drive targeted action plans and strategies working with suppliers, customers, and partners to address the specific opportunities and challenges within this decade, and as we close in on 2050.”

About the Author(s)

You May Also Like