AMP Robotics Pilots Automated Secondary Sortation Facility to Increase Recycling Rates

March 4, 2021

Denver -- AMP Robotics Corp. (“AMP”), a pioneer in artificial intelligence (AI) and robotics for the waste industry, has piloted an automated facility design for advanced secondary sortation. The company-owned test facility, located in Denver, serves as an infrastructure model that economically can process and aggregate small volumes of difficult-to-recycle mixed plastics, paper, and metals sourced from residue supplied by primary MRFs.

“Secondary sortation efforts are not new, but have been held back by how to make it work economically and at scale,” said Matanya Horowitz, founder and CEO of AMP Robotics. “AMP’s application of AI for material identification and advanced automation has matured to the point where it’s now feasible to develop low-volume secondary sortation facilities that are economical to deploy and sustain nationally. Results we’ve observed at our test facility are promising and represent an infrastructure solution that can increase recycling rates, divert recyclables from the landfill, meet the growing demand for recycled content, and protect our environment.”

With the United States recycling less than 33% of recyclable materials overall—and just 9% of plastics—produced annually, the ability to recover recyclables from residual waste streams represents a major opportunity to increase national recycling rates. Residual waste is the difficult-to-recycle material left over from primary MRFs that is typically sent to landfill. Residue contributes to the millions of tons of recyclables and billions of dollars worth of material feedstock lost to landfill despite the demand for recycled content from consumer packaged goods companies and manufacturers.

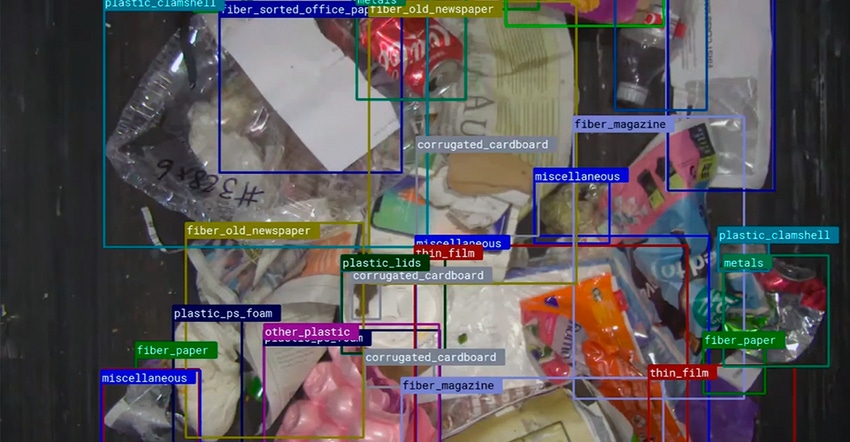

AMP’s next-generation secondary sorting facilities apply advanced automation enabled by AI to economically sort through these low volumes of residue to recover mixed plastics like PET, HDPE, LDPE, PP, and PS. These material streams also contain high-value recyclables like used beverage cans (UBCs) and old corrugated cardboard (OCC) that are in high demand for resale to aluminum manufacturers and paper mills. AMP’s secondary facilities drive down the cost of recovery while creating contamination-free, high-quality bales of recycled material for resale. AMP’s business model also introduces market certainty and new revenue streams for established MRFs by creating demand for residue that would otherwise cost businesses to dispose of.

With the success of its pilot, the company plans to roll out a number of secondary facilities in other parts of the country during 2021. AMP is actively seeking to expand supply partnerships with waste management companies to acquire residual waste. The company is also working with an undisclosed group of end-market buyers for the sale of its recycled bales of plastics, paper, and metals.

Last month, AMP announced it raised $55 million in corporate equity in a Series B financing, led by XN with participation from new investors Valor Equity Partners and GV as well as existing investors Sequoia Capital, Sidewalk Infrastructure Partners, Congruent Ventures, and Closed Loop Partners. This new round of funding followed a $16 million Series A financing led by Sequoia Capital in November 2019.

About AMP Robotics™ Corp.

AMP Robotics is modernizing the world’s recycling infrastructure by applying AI and automation to increase recycling rates and economically recover recyclables reclaimed as raw materials for the global supply chain. The AMP Cortex™ high-speed robotics system automates the identification and sorting of recyclables from mixed material streams. The AMP Neuron™ AI platform continuously trains itself by recognizing different colors, textures, shapes, sizes, patterns, and even brand labels to identify materials and their recyclability. Neuron then guides robots to pick and place the material to be recycled. Designed to run 24/7, all of this happens at superhuman speed with extremely high accuracy. With deployments across North America, Asia, and Europe, AMP’s technology recovers recyclables from municipal waste, precious commodities from electronic waste, and high-value materials from construction and demolition debris. AMP is made in America with headquarters and manufacturing operations in Colorado.

You May Also Like