Waste and Recycling Fire Season Has Officially Started, May 2022 Sees Most Fires Ever

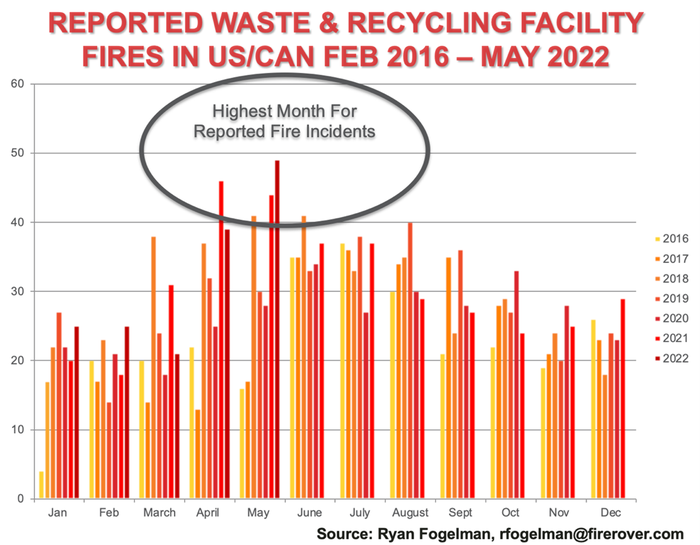

May of this year was the worst on record since I began reporting waste and recycling facility fire incidents in 2016. In May, we incurred 49 reported fire incidents. This was the worst month ever recorded, surpassing April and May of last year when we encountered our worst months of 46 and 44 fire incidents, respectively, and far surpassing our monthly historical average of 28 reported fire incidents per month.

May of this year was the worst on record since I began reporting waste and recycling facility fire incidents in 2016. In May, we incurred 49 reported fire incidents. This was the worst month ever recorded, surpassing April and May of last year when we encountered our worst months of 46 and 44 fire incidents, respectively, and far surpassing our monthly historical average of 28 reported fire incidents per month.

What is Fire Season?

If you look at the data, one thing is clear: the summer months are our worst months for fires. Not only is this trend consistent year over year, but it also is consistent in our Fire Rover client saves. Fire season typically begins in April, but we’ve seen it come early some years and later in others. The fact is that hot and dry environments increase the risk and severity of fire incidents. If you look at the news, we are in the middle of some of the hottest months on record in both the U.S. and Canada, and wildfires are spontaneously combusting in Nevada and Arizona.

Is this Year Historically Different?

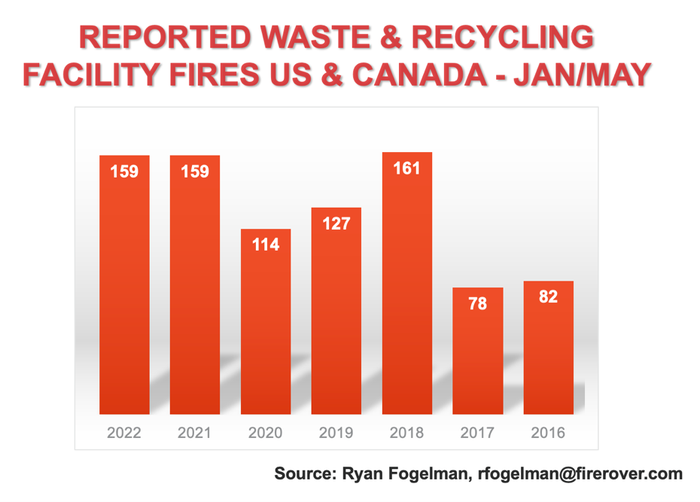

We have experienced three of our worst months for reported fires in the past 13 months. When we look at the historical trend on an annual basis, we see that 2018 and 2021 were the worst two years for the industry. I estimated 2022 based on a weight run rate using the actual data from January through May, and if we keep on pace, 2022 will come in worse than either year or well above the historical average of 326 reported fires.

When it comes to data, you will always hear me say that we really don’t know anything until we see how the future turns out. With that being said, we can look at patterns and similarities/differences in trends.

To see where we are from a run rate, I compared all years’ data from January through May. To no surprise, the numbers were in line with their end-of-year totals.

Was There a Particular Sector Driving the Increase in Fire Incidents?

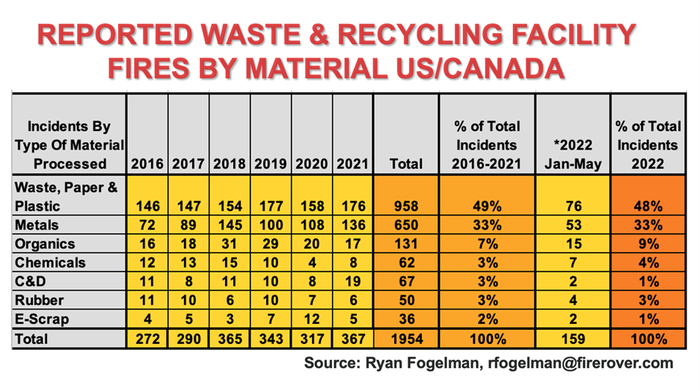

There have been times in the past when certain materials made up a larger percentage of fire incidents over a period of time. I looked at the data from the chart above where I broke out the materials for the historical timeframe. It is clear that we are seeing materials close to their historical norms, give or take a few percentage points, not the specific occupancies having a major change.

How are the Fire Rover Customers Faring During this Time?

At Fire Rover, we put out 124 fires in the month of May, far surpassing March and April, which came in at 67 and 81 fire incidents, respectively, at our 350 client locations. The truth is our clients’ incidents and saves are typically high when publicly reported incidents are high and come down when they come down. It seems that fire season is fire season.

I have always been under the impression that as our Fire Rover solution is protecting more and more materials recovery facilities (MRFs), transfer stations, scrap metal facilities, electronics, hazmat and more, the number of reported fire incidents would begin to come down. We haven’t seen that yet. In fact, we have experienced the exact opposite. We only protect a small percentage of the operations in the U.S. and Canada. We are protecting some of the largest operations, but as we continue to install our solutions, there will be a time when we are going to see a noticeable difference in reported fires and funds lost on these properties.

Our waste and recycling operators are the victims.

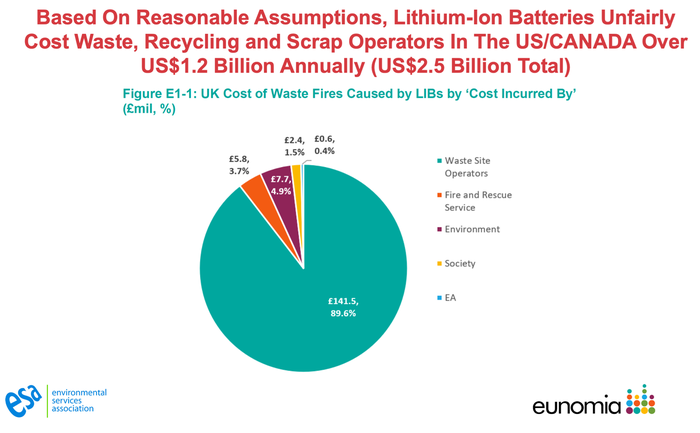

I have shared this before, and I certainly do not want to make our operators appear weak, but it is a fact that waste and recycling operators are the victims when it comes to a number of the hazards they deal with on a daily basis, including the surge of lithium-ion batteries in our waste and recycling streams. This ideation of “victim” is a purely economic rationale. When you take a macro view of the battery supply chain, there are so many beneficiaries from a profit, productivity and enjoyment of life perspective. The only real costs of the downside fall squarely on our industry. Lithium-ion batteries conservatively cost our industry in the U.S. and Canada $1.2 billion dollars annually. It is time that we demand that the battery manufacturers pay their fair share of the $1.2 billion dollars in costs our industry’s operators and fire professionals have up to this point been unfairly burdened with.

Where Do We Go from Here?

Back to the basics—education, training/preparedness and investment in technology.

Education – The most important way to prevent fires is to prevent the wrong materials from getting into the waste and recycling stream in the first place. It has become extremely apparent from my view of the world that most regulations being pushed by governments and associations are seeking funding for more education programs. I am all for education, but we have to consider the following limitations of this approach:

Rules vary by jurisdiction and can cause confusion.

Education only works for waste and recycling; it has little effect on scrap metal, construction and demolition, e-scrap, organics, chemicals and rubber.

Reach is difficult. Certain percentages of the population simply will never learn.

In 2019, Covanta conducted a survey of 2,000 Americans, revealing that although 22 percent of Americans “don’t have enough information regarding recycling,” 21 percent said they are simply “too lazy” to recycle. No matter how much we try to educate the problem away, the reality is that education is only one leg of the stool.

Training/Preparedness – It’s time to get back to basics. I’ve said it before, and I’ll say it again: good operators have fewer fire incidents than bad operators. The numbers show that we had fewer reported fire incidents in the two years since the lithium-ion battery wave hit our industry in 2018. I think we all can agree that we cannot really trust last year’s data since we were in the middle of a global pandemic. The number of incidents was down, but as I mentioned in the annual report, we need to see the next couple of years to truly understand how the pandemic year fits into the story. Our operators have spent the past year rightfully focused on their employees’ safety amid COVID-19. But now, it is time to dust off the fire prevention plans, invite the fire professionals back to meet with your team and ensure that you’re following operational best practices such as the “Guide to Creating a Fire Prevention and Management Plan” developed by the Institute of Scrap Recycling Industries for its members.

Remember, we need to ensure the fire professionals also have the necessary tools and education to help fight any potential fire incidents at our facilities.

Technology– In combination with education and training/preparedness, it is time for industry to realize there is a solution to this problem. As I shared in my risk mitigation article[MS1] a couple of months back, our customers who have developed operational best practices, in combination with having our early thermal detection and fire elimination solution in place, have fewer fire risks.

While we see the value in technology and proper waste management and recycling, we need to get the associations, government entities and lobbyists on the same page. The cost currently burdening the waste and recycling industry needs to be passed to the battery manufacturers of the world. This isn’t because they are the “bad guys;” it’s because they are providing the public what we’re demanding: more access to portable power.

This solution would allow all of the players in the supply chain to share the benefits and costs. For example, in the U.S. and Canada, we have about 5,000 facilities, according to the Environmental Research & Education Foundation, that face harm resulting from lithium-ion batteries specifically. These batteries cost the industry $1.2 billion dollars annually from fire incidents. That is $240,000 per site that we could invest in solutions like the Fire Rover that stop these fires in their tracks.

This approach is universally used in a number of industries. When states legalize gaming, they take a percentage to help those who become addicted. It’s time for the battery manufacturers to fund more than just those efforts that have the greatest visibility, without the greatest effect on safety, especially since this problem is far from going away. According to UBS estimates, over the next decade, energy storage costs will fall between 66 percent and 80 percent, and the market will grow to as much as $426 billion annually worldwide. This is a big problem that requires big solutions!

Conclusion

The truth is that we need to safely recycle lithium-ion batteries for so many reasons other than the fact that they cause fires in our operations. The global future is being built on this technology, and we have less access to rare earth metals than other parts of the world. Every time we throw a battery in a landfill, we lose all the material that could be used to create new batteries and other equipment.

The fire industry is listening to this cry for help and demand for action. I was fortunate to speak at the National Fire Protection Association’s conference in Boston earlier this month on the topic of “Remote Video Monitoring for Early Detection and Suppression.” View the full presentation below:

Lithium-ion battery fires were one of the hot topics being discussed at the show, mostly centered around power farms and fires in transportation. Best practices, technologies and education are in full effect on a national scale, and we must continue these efforts in order to see a reduction in facility fires.

Ryan Fogelman, JD/MBA, is vice president of strategic partnerships for Fire Rover. He is focused on bringing innovative safety solutions to market, and two of his solutions have won the distinguished Edison Innovation Award for Industrial Safety and Consumer Products. He has been compiling and publishing the “Reported Waste & Recycling Facility Fires In The US/CAN” since February 2016 and the “Waste & Recycling Facility Fires Annual Report.” Fogelman regularly speaks on the topic of the scope of fire problems facing the waste and recycling industries, detection solutions, proper fire planning, and early-stage fire risk mitigation. Additionally, Fogelman is on the National Fire Protection Association’s Technical Committee for Hazard Materials. (Connect with Ryan on LinkedIn at https://www.linkedin.com/in/ryanjayfogelman or email at [email protected])

[MS1]add link to article

About the Author(s)

You May Also Like