How Closed-Loop Recycling Programs Benefit Automobile Manufacturers

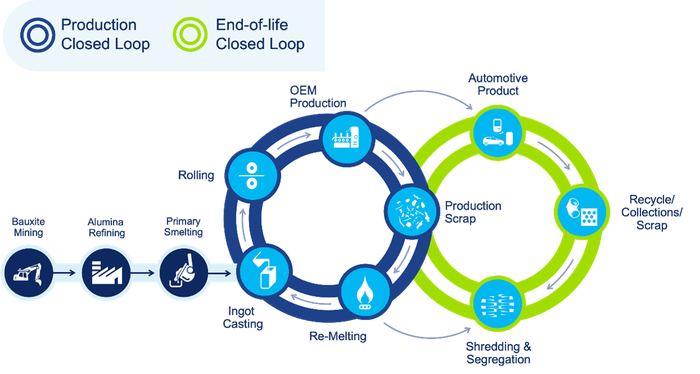

As the global automotive industry strives to reach ambitious sustainability targets, most notably regarding carbon emissions, it continues to gravitate toward the world’s infinitely recyclable material—aluminum. In fact, aluminum can be recycled and reused endlessly without losing its material properties. This phenomenon is the foundation of a circular economy for the automotive industry fueled by closed-loop and end-of-life recycling.

June 14, 2023

Jamie Zinser, Vice President, Global Automotive, Novelis Inc.

As the global automotive industry strives to reach ambitious sustainability targets, most notably regarding carbon emissions, it continues to gravitate toward the world’s infinitely recyclable material—aluminum. In fact, aluminum can be recycled and reused endlessly without losing its material properties. This phenomenon is the foundation of a circular economy for the automotive industry fueled by closed-loop and end-of-life recycling.

To help the automotive industry reduce carbon emissions and ultimately achieve carbon neutrality, as well as reduce waste and preserve natural resources, companies such as Novelis work in partnership with automakers to create and implement customized circular economy programs.

These programs include closed-loop recycling solutions that address the unique infrastructure and business dynamics of each automobile manufacturer.

Here are the top 4 benefits of customized closed-loop recycling programs for automakers.

1. Preserving the value of aluminum alloys: Recycled aluminum is essential for the future of sustainable mobility. A customized, closed-loop and end-of-life recycling program is key to keep like alloys separated, which is critical to maintaining the performance specifications of automotive alloys.

To enable this, aluminum scrap segregation and sorting technologies are critical to any successful recycling program as scrap aluminum can be collected and transformed into new vehicle parts. These processes separate different alloys by refined alloy families. Keeping these alloys separate ensures the same alloy can go back into its original application, which preserves its value, and requires less primary metal input, enabling the conversion of high-quality scrap material into new coils. The use of recycled aluminum reduces the demand for raw materials.

2. Reducing CO2 emissions: Recycled aluminum uses approximately 95% less energy than primary aluminum production, resulting in 95% less carbon emissions. Increasing the use of recycled aluminum improves energy efficiency and promotes a true circular economy. Closed-loop agreements with customers allow the recycling of production scrap into new automotive sheet to enhance the sustainability profile of their vehicles.

3. Establishing a secure supply chain: Using recycled materials in a circular economy system strengthens the automaker’s supply chain and makes its production schedule less vulnerable to disruptions caused by external factors. The average stamping process turns 30%-40% of an aluminum coil into scrap that can be recycled back into the same product, leveraging aluminum’s unique benefit of being infinitely recyclable without losing its material properties.

4. Enhancing economic benefits: Because aluminum is infinitely recyclable, automakers can leverage closed-loop recycling programs to reuse aluminum again and again without impacting its properties. This reduces total vehicle costs and helps maximize the sustainability benefits of aluminum, including its extensive lightweight properties that can enable EV efficiency and allow for traveling longer distances on a single battery charge.

With a common goal of a more sustainable future, the automotive and aluminum recycling industries can work together to develop solutions to make the circular economy a reality today.

About the Author: Jamie Zinser is Vice President of Global Automotive at Novelis, where she is responsible for global automotive commercial strategy.

You May Also Like