Challenges Can Prohibit Routing Software Adoption Despite Innovations

Convincing municipalities and private waste operations to switch to routing software can be challenging since planning methods are still traditionally manual.

New innovations constantly arise in any technology-driven industry. For waste and recycling, the technology surrounding routing software is continuously evolving, but it isn’t always accepted.

Route optimization, in general, is a complex math problem, says Tony Esposito, president and CEO of C2Logix Inc.

“The algorithms that are used are designed to solve specific types of routing problems, taking into account various parameters and constraints to ensure the route fits the way the client wants to operate their business,” he says. “These parameters include but are not limited to things like arrival time windows, capacity constraints, variable visit durations and many more. The program will try potential route scenarios until it finds a route that is efficient and meets the parameters in the best possible manner.”

The emergence of handheld devices has enabled a surplus of new capabilities in-cab for routing software.

“Today, navigation is available to everyone via the smartphone. However, the navigation software alone doesn’t satisfy a complex network of waste collection trucks in either residential or commercial situations,” says Lasse Jiborn, director of intelligent optimization at AMCS Group. “The navigational software in today’s handhelds, albeit sophisticated, including somewhat reliable up-to-the-minute weather and traffic conditions, aren’t enough to solve the complex challenges of a fleet of waste trucks.”

AMCS’ route optimization solution includes technology for incremental optimization. The solution receives live data from surrounding systems and instantly absorbs the data and performs automatic and incremental re-optimization.

“This paves the way for an agile waste company, with optimization running in all the stages of planning, scheduling and execution,” says Jiborn.

C2Logix also has experienced opportunities, given its ability to take the optimized routes from the office and offer electronic, visual and audible navigation in the cab of the vehicle, including the ability to view the progress back at the office in real time.

“The system is exception based, which means that the driver does not need to interact physically with the device except when there is something outside of normal operating procedures, such as notating that a bin is broken or the recycling is contaminated,” says Esposito.

C2Logix offers two route optimization solutions that solve two different types of routing problems. FleetRoute is for high-density routing problems such as residential routing, where you typically need to stop at every home, on every street, from the right side of the truck, etc.

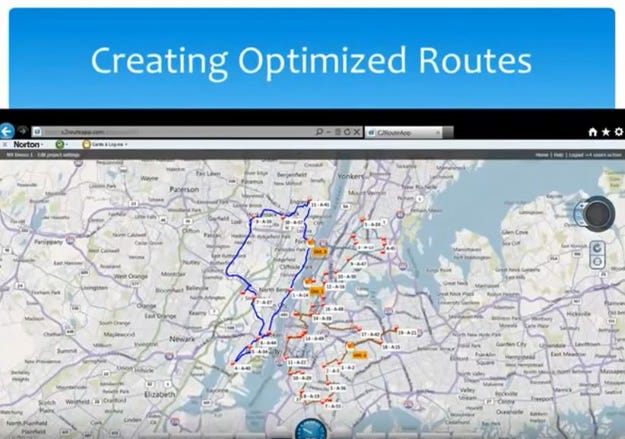

For low-density applications such as commercial waste, roll off and cart maintenance, the company offers C2RouteApp, a web-based application for routes that are more point-to-point in nature and change regularly.

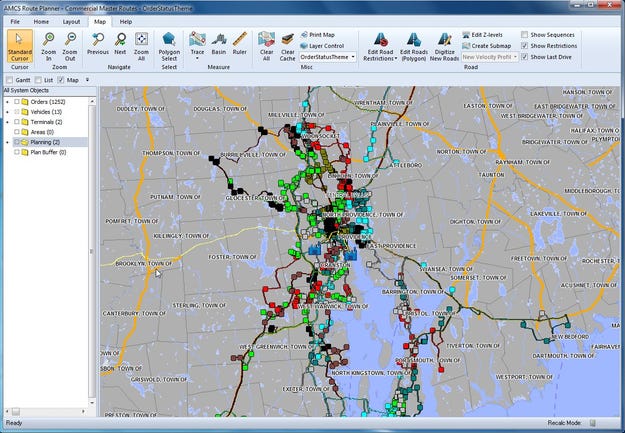

RouteSmart Technologies Inc. offers its RouteSmart RaaS (Routing as a Service) to help clients in the industry leverage RouteSmart solvers in the cloud. Roll‐Off Route Optimization takes advantage of RaaS and provides a way to make roll‐off routing much more efficient, and Route Health Score provides an objective way of measuring the impact of route optimization.

“Our suite of software includes the navigation of a single route with turn-by-turn navigation, and it's also combined with one of the markets' most efficient optimizing engines,” says Jessica Cearfoss, business development manager of public works for RouteSmart. “Our solution will plan and coordinate all routes for residential and commercial waste trucks, and once the master routes are laid out, our systems allow for real-time changes to the routes based on the most efficient optimization, taking into account all current conditions and limitations.”

RouteSmart’s solvers for each segment of the public works industry (residential, commercial, roll‐off, street service) are what make the solutions stand out, according to Cearfoss. In addition to the solvers, the solution relies on GIS (geographic information systems) technologies on the Esri platform, as well as current street data.

The AMCS software is a cloud-based solution that runs with abilities to multitenancy, and the in-cab solution is a web-based solution that makes it compatible with any platform, also supporting BYOD (bring your own device) strategies.

Despite innovations, convincing municipalities and private waste operations to switch to routing software can be challenging. Planning today is traditionally manual, using Microsoft Excel or similar tools. Selecting between routing solutions can be difficult because of lack of baseline.

“The data used today is not very reliable. Roads change, waste bins are moved, different drivers make different decisions when collecting, etc.,” says Jiborn. “Software companies offering optimization software are not often from the waste industry, and they don’t necessarily understand the challenges.”

Esposito says it can be the fear of the unknown and lack of guarantees.

“When purchasing anything, including new technology, there are typically no guarantees in the results,” he says. “If the route optimization study does not show a significant savings, many people are afraid of the repercussions that might come down if they spend money on something that does not produce results.”

The cost of route optimization systems can prohibit municipalities and private operations from choosing waste routing software.

“After implementation, the benefits far outweigh the costs, but the pain may be too much for many groups to get the ball rolling,” says Cearfoss. “Purchase of a new system, and the subsequent user training, can be a big hurdle.”

According to Jiborn, a solid waste collection operation can gauge its need for route optimization software by looking into complaints or how many bins are missed each week.

“It is really pretty simple. Look at the bottom line,” says Esposito. “If the operation is not satisfied, then route optimization has the ability to drop a bundle on that bottom line by reducing the number of vehicles, work hours, overtime, etc.”

Cearfoss says the need for route optimization software is based on two factors: a desire to operate efficiently and a desire to grow.

“Every organization needs to operate at peak efficiency,” she says. “The industry has become ultra‐competitive in recent years, and all aspects of operations must be scrutinized. If an organization is feeling the pinch from competitors, operating cost or other factors, they need route optimization … If a company has any desire to expand beyond its current operations, route optimization is a must.”

About the Author(s)

You May Also Like