DIY Fire Protection Versus Outsourced Fire Protection

Despite the polluted image environmentalists give to operators, the waste and recycling industry continues to work day and night to keep tonnage out of landfills. Now that the summertime spike of reported facility fires has passed, Ryan Fogelman looks at trends and data to show how 2023 will be another "record year" for fires and what can be done to prevent them at your facilities.

Fighting fires is no easy task, especially a fire that begins within a waste or recycling facility. In this month’s column, I explore why it’s important to be prepared for a facility fire and explain the difference between DIY fire protection and outsourced fire protection.

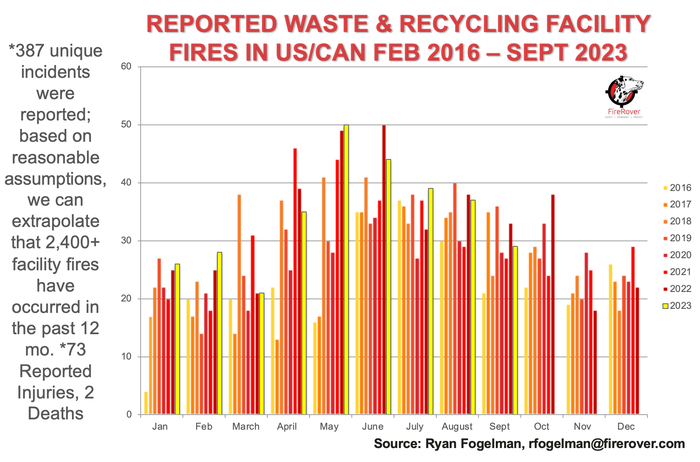

September 2023 Fire Data

In September, we encountered 29 publicly reported fire incidents at our waste and recycling facilities. Of those incidents, 14 occurred at waste, paper and plastic facilities, 12 occurred at scrap metal recycling facilities and three occurred at organics sites. At Fire Rover, we responded to 350-plus hot spots and/or fire incidents at our clients’ facilities.

As you can see from the data, we typically trended down in most of the past Septembers, coming off the highs of the “summertime spike” in fires we usually see in the preceding months.

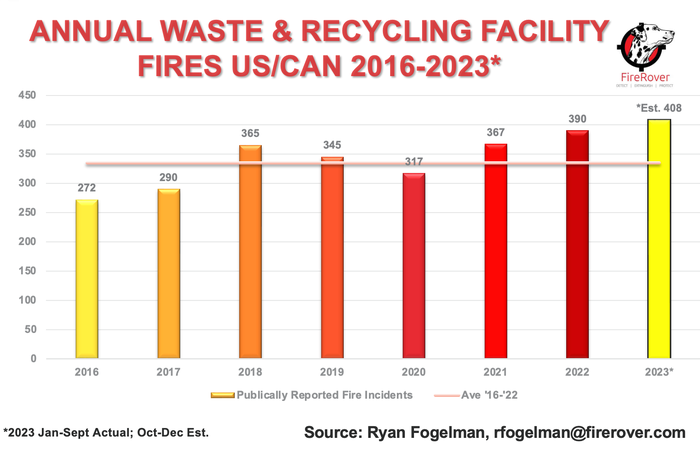

Good or bad, we still have October, November and December; however, by doing a simple forecast based on the previous month's average, we are trending for an increase in overall reported fire incidents in the U.S. and Canada from last year. Barring any abnormalities in the next three months, it looks like it is going to be another “record year” for fires in our waste and recycling streams, continuing the trend of “record-high fire incidents” over the past three years.

To get a true picture of the increasing fire risks the waste and recycling industry is facing, you must consider that Fire Rover has more than 500 different systems protecting more than 400 individual transfer stations, materials recovery facilities, scrap metal operators, electronic recyclers, compost facilities, rubber facilities and environmental/hazardous waste sites across the U.S., Canada, Australia, UK and France. With our track record, it cannot be argued that our customers are not the ones having incidents that get to the level of requirement to be “reported” by the media. During the last twelve months, even the incidents that overlap due to a fire occurring outside our area of protection can be counted on one hand.

The reality is the threat is still growing. Even with our efforts to educate the public or corporations about the dangers of fires in our waste and recycling streams, it is not moving the needle. The dangers are increasing in volume and we are losing ground. For example, at very conservative estimates, millions of vapes are tossed in waste and recycling bins in the U.S. and Canada each month. No matter how much we do to prepare and train, certain solutions to the problem should be prioritized.

Put another way, educating the public has very little effect on the hazards entering the waste and recycling streams. I am not suggesting we abandon this approach. It is simply a long-term horizon. We need to focus on continued operational “best practices” and technology like our Fire Rover solution that has proven that it works effectively, reducing damage and losses at a higher rate than any alternative approaches. I am not suggesting that our solution is the only one out there; there are other promising innovations, like robotics on the pre-sort lines, that can effectively remove a significant portion of these batteries coming soon, but the reality is that we need to get behind the solutions that are most effective to stop the losses to our nation’s critical waste and recycling infrastructure.

The Summertime Spike

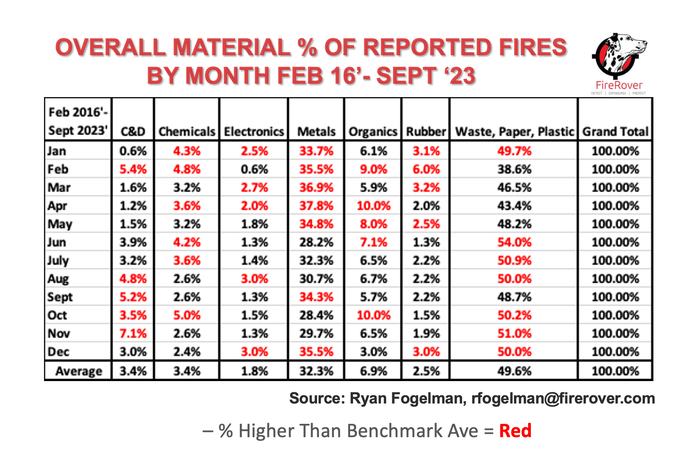

Now that we have presumably passed the summertime spike of reported waste and recycling facility fires we traditionally see during the summer months, I decided to dive a bit deeper to ascertain any trends we might be able to learn from. In the following table, I used actual data going back to February 2016 to get a look at fires by material by monthly occurrence.

My goal is for readers to look at their specific occupancies and provide their thoughts and insights on why/if we are seeing trends or if this data is purely arbitrary.

As you can see from the chart, it seems certain trends we have been experiencing are reconfirmed. For example, I would expect to see a higher percentage of fires during the summertime months for waste, paper and plastic operations because there is typically an increase in specific hazards in the waste and recycling streams such as fireworks, propane tanks and BBQ briquettes to name a few.

In our scrap metal operations, we saw higher-than-benchmark fires during December-May, with a spike in September than the rest of the year. My gut tells me the increase is due to the decrease in waste, paper and plastic fire incidents, which is trending almost in the opposite step with scrap metal.

When it comes to construction and demolition fire incidents, there seems to be a larger percentage in the second half of the year, which might have something to do with the material flow during that timeframe.

Organics operations, on the other hand, saw a 50% increase in fires during October and April, which could have something to do with the time when there is an increase or decrease in temperature and changes in wet and dry seasons.

DIY Fire Protection Versus Outsourced Fire Protection

Employees have been on the frontlines fighting fires at our waste and recycling operations since the beginning of time. They have been the heroes of owners, operators, fire professionals and others. This is not a bad thing; it is actually quite the norm in the fire protection business. There are 1.2 million firefighters in this country, and the majority of them have volunteer status. They are “generalists” in the fire world, only putting themselves at risk when someone's life is in harm's way. They are good at what they do most, so unless you are in a heavily industrial area, you are not trained to fight the specifics of every occupancy’s fires. Most fire professionals will allow and might require, the industry professionals to educate and partner at the very minimum to put fires out.

When hazards are high enough, like we see in refining, companies have and train a formal fire brigade. A fire brigade is an “insourced fire protection” solution that works on the frontlines of a fire or explosion with the regional fire professionals as partners and backup when needed.

These hazards have caused waste and recycling operators to do things like purchase their own fire trucks to help with the problem. I am not saying you should purchase your own fire engine to deal with the threat of lithium-ion batteries in your waste and recycling operations, but it is understandable why the operator made that choice. With the proliferation of these hazards in our waste and recycling streams, operators are faced with these fires every day.

In this article by The Courier, the firm's Transport Director Irvine Morrison said, “That crucial first 10-15 minutes could be the difference between containing a blaze and a potentially catastrophic fire taking hold. The fire appliance isn’t meant to be a replacement for the fire service.However, given that we don’t have a fire station nearby, it will allow us to act in those crucial minutes before firefighters arrive.”

The first 15 minutes are critical, and if there is water or equipment for fire professionals to use when on the scene, that’s a bonus. But there is a downside.

I recently interviewed Russ Kane MSc. CFO CWMS, fire chief at Galeton Fire Protection District-Galeton Fire Rescue in Colorado, to discuss how sites should protect themselves and what he thinks about having a fire truck onsite to protect operations.

“Buying an old fire engine with a 1,000-gallon booster tank, keeping it ready to go and having trained operators/firefighters to run it is a monumental task not typically suited for most companies I have come across in the waste and recycling industry,” he says. “If the fires are not caught early enough, water alone may be 100 times that if not discovered in the incipient stage like your Fire Rover system seems most successful with.”

“Having a good emergency system with a plan and trained personnel, fixed fire protection systems, pile storage management consistent with NFPA [National Fire Protection Association], a good pre-plan with the authority having jurisdiction and first responders and perhaps an automated dynamic system like the Fire Rover is ideal.”

As you can see, fighting waste and recycling facility fires requires specialized equipment. Look at the waste-to-energy facility fire footage below as an example.

Our Fire Rover early detection, fire elimination solution focuses on the initial 10 minutes between when a fire starts and when fire professionals arrive on scene. More importantly, though, is that it starts looking for symptoms of a fire before stretching those initial 10 minutes. Additionally, our solution allows the customer to wait in a safe location until our remote agents deal with the fire.

When your frontline defense for a fire is your employees, they need to be properly trained, equipped and insured!

Proper Training and Equipment: There is a fine line between a fire brigade and informally fighting a fire. Using fire equipment is just one of the factors the Occupational Safety and Health Administration uses to define an active fire brigade. Training the responding fire department with the unique hazards it will face is important, but many companies like Rumpke Waste & Recycling based in Ohio do a great job educating first responders.

The fire brigades need training, equipment and qualified staff. The issue that most of us in the industry need to worry about is the proliferation of lithium-ion batteries in the waste and recycling streams. Major fire associations, including NFPA, recently created material around “Firefighting Operations with Lithium-ion Batteries,” stating in its overview:

Li-ion battery or ESS [energy storage systems] fires pose a unique hazard to firefighters. They produce toxic gasses, create explosive environments, are difficult to get water to, reach flashover in as little as 24 seconds and always pose an electrocution hazard.

For all responses, ensure a Risk Management Plan is implemented.

All operating personnel shall work within a standard Risk Management Plan during all emergency operations on every emergency incident. This application will be continuously re‐assessed at all levels of the incident until all units leave the scene.

1.We Will risk our lives a lot, in a calculated manner, to save savable lives.

2.We Will risk our lives a little, in a calculated manner, to save savable property.

3.We Will Not risk our lives at all for lives or property that are already lost.

All types of fires involving Li-ion batteries have similar hazards. The size and scope of the problem is directly tied to the size of the battery and the state of charge.

When fighting these hazards from personal electronics or micro-mobility fires, the NFPA advises specifically, “Upon recognition that it is a Li-ion fire, a direct attack with water is preferred in full PPE [personal protective equipment] with face piece.”

When lithium-ion batteries enter thermal runaway, they let off noxious gasses that could potentially pose health hazards to employees and fire professionals fighting a fire. Anyone fighting battery fires should be properly protected from flames and any released gases.

Properly Insured: There is an effect on premiums whether you have a formal fire brigade versus informal versus none, but acting as an informal fire brigade can have severe consequences if something goes wrong.

Fighting fires early is important and critical, but bringing the “water, water, water” approach results in a ton of firewater that after being used requires proper disposal and environmental cleanup. The earlier you catch, contain and suppress a fire, the better the results, which is exactly why our Fire Rover solution has been so successful in dealing with the hazards our clients face every day!

Conclusion

I think we are all aware by now that one size does not fit all as every company has different resources. While some might have no problem affording to develop, train and implement an internal formal fire brigade, most operators do not have that luxury. At Fire Rover, we are the “outsource fire brigade” for most of our customers, and we offer two main solutions for indoor and outdoor fire hazards: our boxed solutions and our continuous flow solution. These run off a fire loop when outdoors and the water lines when installed indoors.

The reality is that certain environmentalists are publicly lashing out at the waste and recycling industry. They say they love recycling, but all I see is the narrative that the waste and recycling industry is dirty, loud, polluting and hazardous to the environment. In actuality, these operations are what keep the tonnage of material from being placed in a landfill to rot for the next century. We need solutions to these problems and fierce battles by the local jurisdictions with the “not in my backyard” mentality, not a pat on the back for the idea of what our industry does. If you are attending the MRF Forum/PPRC in Chicago or are attending the Automotive Recyclers Association Conference & Expo this week, feel free to stop by my booth and the “High Level EV Panel” on Friday at 11:00 am CST to connect. I will also be presenting virtually at, "The Impacts of Improper Battery Disposal" during Encamp's Batteries Compliance Summit held on Wednesday, October 11th.

Ryan Fogelman, JD/MBA, is vice president of strategic partnerships for Fire Rover. He is focused on bringing innovative safety solutions to market, and two of his solutions have won the distinguished Edison Innovation Award for Industrial Safety and Consumer Products. He has been compiling and publishing the “Reported Waste & Recycling Facility Fires In The US/CAN” since February 2016 and the “Waste & Recycling Facility Fires Annual Report.” Fogelman regularly speaks on the topic of the scope of fire problems facing the waste and recycling industries, early detection solutions, proper fire planning and early-stage fire risk mitigation. Additionally, Fogelman is on the National Fire Protection Association’s Technical Committee for Hazard Materials. (Connect with Ryan on LinkedIn at https://www.linkedin.com/in/ryanjayfogelman or email at [email protected])

About the Author(s)

You May Also Like