Profiles in Garbage: Polyethylene Terephthalate (PET) Bottles

Polyethylene terephthalate (PET) is a plastic resin used to make bottles for beverages, food, and other household and consumer products. PET is a relatively new packaging resin. The PET bottle was patented in 1973. Four years later, the first PET bottle was recycled.

For many years, soft drink bottles were the biggest user of PET resin. “Custom” bottles are used for other products such as salad dressing, peanut butter and jellies. Custom bottles now account for more than half of PET containers by weight. PET is also used for film, oven trays, sheeting for cups and food trays, oven trays and other uses. This Profile is limited to PET containers.

The market share between domestic and export markets has changed since 2003. Ten years ago, domestic markets were predominant. In 2006, export markets overtook domestic markets. However, export markets peaked in 2008. In 2013 exports represented only 26 percent of PET markets.

Increased consumption of water and soft drinks away from home along with continued lightweighting of PET bottles has created challenges for increasing the PET recycling rate. Increased use of PET bottles has reduced the size of the waste stream because they replaced heavier steel and glass containers.

PET Packaging MSW Facts

(* = U.S. Epa Estimates for 2012)

Generated

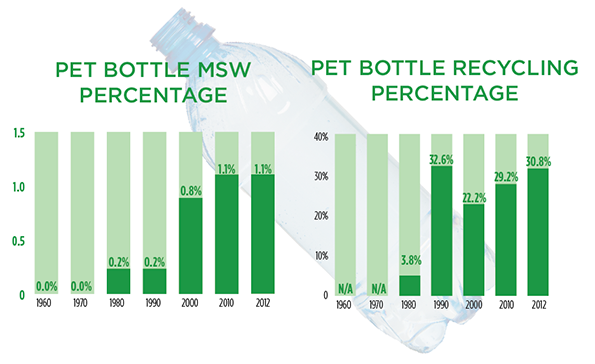

2.79 million tons or 1.1 percent by weight.*

17.78 pounds of PET bottles per person.*

18 20-oz soft drink bottles weigh one pound.

Recycled

860,000 tons, or a 30.8 percent recycling rate.*

899,000 tons or a 31.2 percent recycling rate in 2013 according to industry data.

Container deposit laws make soda and water bottles easily recyclable.

Recycled Content

Approved by FDA, use in bottles is increasing.

Composted

PET does not compost.

Burned or Landfilled

1.93 million tons or 1.1 percent of discarded MSW by weight.*

Highly combustible, with a per-pound Btu value of 10,933, twice that of MSW.

Landfill Volume

2.76 million cubic yards or 0.7 percent of landfilled MSW were soft drink bottles in 1997.

Density

Landfilled bottles weigh 355 pounds per cubic yard (lbs/cu.yd.).

Whole bottles have a density of 30-40 lbs/cu.yd.

Baled bottles have a density of 400-500 lbs/cu.yd.

Source Reduction

The 2-liter soft drink bottle weighs 48 grams and is 20 grams or 29 percent lighter than 20 years ago.

The half-liter water bottles can weigh less than 8 grams and has lost twice its current weight since 1991.

The number of PET containers increased by 4% in 2011, but the weight increased by only 2.4 percent.

Recycling Markets

Fiber, food and beverage bottles and sheet and film are the primary domestic markets.

Half of all polyester carpet made in the United States is made from recycled PET bottles.

Exports were the largest market for PET recyclers in 2006. An increase in U.S. reclamation capacity dramatically changed this trend, with only 26 percent of PET bottles being exported in 2013.

End Market Specifications

ISRI Scrap Specifications Circular 2015: Guidelines for Plastic Scrap: P-2015 includes PET Mixed Bottles from curbside collection. Contamination is limited to 2 percent. Must be dry and if stored outside not damaged by ultraviolet exposure.

Non PET plastics and injection grade are considered contaminants.

Sources

Municipal Solid Waste Generation, Recycling and Disposal in the United States: Facts and Figures for 2012, USEPA, Office of Solid Waste, 2013

Report on Postconsumer PET Container Recycling Activity in 2013, National Association for PET Container Resources & The Association of Postconsumer Plastic Recyclers

Scrap Specifications Circular 2014, Institute of Scrap Recycling Industries, Washington, D.C.

About the Author(s)

You May Also Like