A Cogeneration Solution for Evaporating Landfill Leachate

The Three Rivers Regional Landfill maximizes value by evaporating leachate with Heartland’s Hybrid CoVAP™ Solution which combines the exhaust from an on-site waste-to-energy plant with the thermal energy from a landfill gas flare.

April 6, 2021

Sponsored Content

Case Study Overview

Operators of the Three Rivers Regional Landfill (“Three Rivers”) desired a simple onsite solution for managing their landfill leachate. Key for Three Rivers was controlling leachate management without having to rely on offsite trucking and disposal, reducing its leachate costs and creating long-term cost certainty. Heartland’s proven LM-HT™ Concentrator met Three Rivers goals and more. Three Rivers uncovered unique value and flexibility by using Heartland’s proprietary Hybrid CoVAP™ solution. Hybrid CoVAP is a configuration where exhaust heat from Three Rivers existing waste-to-energy facility (e.g. Cogeneration) is combined with thermal energy from a landfill gas (LFG) flare (e.g. Hybrid) to evaporate leachate. The Hybrid CoVAP solution allows Three Rivers to maximize the value of itslandfill gas and realize the lowest life-cycle cost for its leachate management.

Challenges

Three Rivers, like many landfills, had a long- standing relationship with its local publicly Owned Treatment Works (“POTW”) which had been accepting 12,000 to 24,000 GPD of its landfill leachate for many years.

Unfortunately, transport and disposal (“T&D”) costs were consistently rising and Three Rivers was paying over $0.09/gallon for off-site leachate disposal. Adding to Three Rivers concerns was talk that the local POTW may discontinue accepting leachate and the T&D cost for the next closest disposal outlet would be over $0.20/gallon.

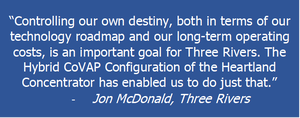

Faced with rising costs and the threat of a steep change that could double or triple its costs without warning, Three Rivers took proactive steps to ‘control its own destiny.’

Action

Three Rivers conducted a comprehensive RFP looking at onsite leachate management options. Three Rivers was clear on its requirements.

Find a trusted vendor with a proven solution on-site leachate treatment

Select a partner to completely design and install the solution

Find a solution that would not rob LFG from its existing waste-to-energy facility

The solution needed to be simple to operate.

Abide by its Title V Air permit requirements

Meet an expectation of a twenty-year product life

Solution

After extensive analysis, Three Rivers selected the lowest total life-cycle cost option that met its requirements, which was the Heartland Concentrator in a 25,000 gpd Hybrid CoVAP configuration.

Figure 2. Heartland Concentrator shown prior to building construction

Hybrid CoVAP™ Configuration

CoVAP™ stands for Cogeneration for Industrial Evaporation. The Heartland Concentrator was designed and patented for using waste heat from engines or turbines beneficially to evaporate wastewater. This is a classic Cogeneration solution. A Hybrid CoVAP™ configuration combines cogeneration with additional heat from a landfill gas flare. This configuration is particularly valuable when you want to use the thermal energy from cogeneration beneficially but there is insufficient heat to evaporate all your leachate.

The Hybrid CoVAP solution provided clear economic benefit to Three Rivers by allowing Three Rivers to run at full capacity while using less LFG. This capability maximizes the value of landfill gas by always running the energy plant and never having to compromise between generating renewable energy and evaporating leachate.

The flare design provides sufficient thermal energy to run the evaporation plant at capacity, if required, without the need for the exhaust from the energy plant should the energy plant be down for any reason. A simple and easy-to- configure control system automatically balances thermal demand between the flare and the engine waste heat.

Cogeneration

The Heartland Concentrator is designed to evaporate 25,000 gallons per day. Thermal energy from the exhaust of the on-site 2G supplied 999kW Caterpillar-MWM Landfill Gas engine is sufficient to evaporate 5,000 gallons of leachate per day. The balance of the required heat for evaporation is provided by the landfill gas flare.

Figure 3 shows the integration between flare and on-site engine. This simple integration drafts the waste heat from the engine exhaust stack. Consequently, there is no backpressure whatsoever placed on the engine making this a safe, and fail-safe, integration.

Figure 3. Hybrid configuration showing (1) integration to engine exhaust and (2) landfill gas flare

Performance Optimization

The Three Rivers Operating Team are very experienced operators. In a joint development effort, Heartland and the Three Rivers Operating Team collaborated on many aspects of performance optimization including additional automation to improve productivity and enhanced clean-in-place to extend routine maintenance cycle-times. The Teams continue to collaborate long past commissioning and strive to uncover new understanding and methods in the never-ending journey of continuous improvement.

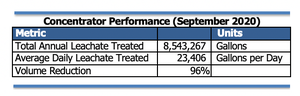

As of September 2020, Three Rivers had treated an average of over 23K gallons per day of landfill leachate achieving volume reduction of over 96% and over 90% up-time.

Table 1. Concentrator Performance, September 2020

Conclusion

Prior to installing the concentrator, 3 Rivers was spending a minimum of $0.095 per gallon in transportation and disposal costs and faced the possibility of costs increasing to levels above

$0.20 per gallon. With Heartland’s concentrator, Three Rivers estimates total cost, including operating costs and capital recovery, to be

$0.06 per gallon. Importantly, the system is in place for the long-term providing cost-certainty for Three Rivers and giving Three Rivers the full control of their leachate treatment.

You May Also Like