Taming the Li-Ion: Why US and Canadian Operators Lead the World in Containment of Lithium-ion Battery Hazards in Our Waste and Recycling Streams

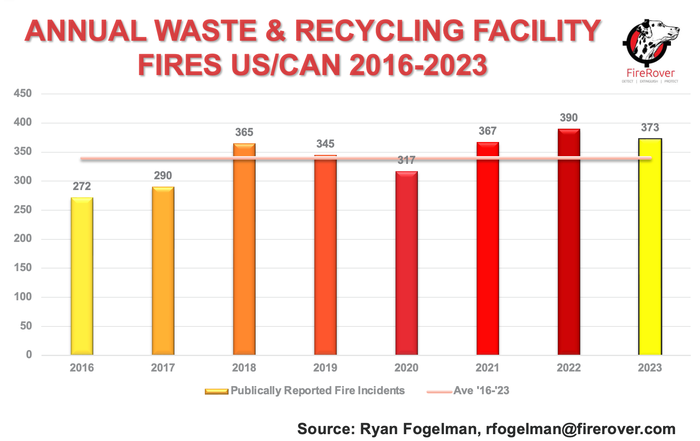

The reality is most people don’t like change. Sometimes change is self-driven, but usually, there is an outside force that drives us to change. In this case, the hazard, as you can see from the increased fires from 2016 to 2018, was truly driven by an increase and unpreparedness for the lithium-ion battery onslaught that punched the industry in 2018.

When new technology hits the market, there is a lifecycle that every solution goes through to make it to the wide adoption stage. So many companies go down this path only to fizzle out well before the wide acceptance stage. For Fire Rover, we started developing our technology solution in 2015. Our technology is really a culmination of different layers that not only include the technology but also a solution integrating people, software, service, warranty and more. When we started Fire Rover, there was no guarantee our solution would work, nor was there a guarantee it would be adopted by customers.

Fortunately, during our inclination stage, we had some amazing partners in the scrap and recycling industry with a burgeoning problem invading their commodity streams: lithium-ion batteries. These batteries were an impending threat to the business' very existence. Compounded forecasts for these hazards, added to the base of traditional fire hazards already inherent in the business, made for a significant shakeup that required new and innovative solutions to deal with the hazards.

The reality is most people don’t like change. Sometimes change is self-driven, but usually, there is an outside force that drives us to change. In this case, the hazard, as you can see from the increased fires from 2016 to 2018, was truly driven by an increase and unpreparedness for the lithium-ion battery onslaught that punched the industry in 2018. The fire experts and operators did what they had always done when dealing with traditional fire hazards in the waste and recycling industry: clean up their operations and develop processes and “best practices” to deal with the problem.

At that time, some of our customers started looking to fire technology for a solution to the impending problem. The reality is the fire industry has been utilizing the same approach to fight fires for well over a century: “water, water, water.” Sprinkler and deluge systems have become the standard across all industries and commercial and residential fire hazards across the globe. However, traditional sprinkler systems, which are required by law in most jurisdictions, are only there for the purpose of “containment,” not initial extinguishment or final extinguishment. In areas that had fast-moving, explosive fires, typically due to accelerants like jet fuel, the fire industry pushed and implemented expansive foam deluge solutions that were not only expensive but came with headaches, like false deluges, which could severely hurt anyone caught inside, as well as ruin any equipment.

As we continued to press on, it became clear there were two sides to both the operators and the fire protection experts: those for change and innovation, and those against change and innovation. I am certainly not saying that those against or skeptical of innovation were in any way unjustified. Many technologies come and go. Operators and fire professionals have been “sold” the idea of a new technology solving a problem hundreds of times before. Typically, these solutions had limitations on how they could perform when in a real environment. Many of our early adopter customers took risks, both monetarily and with their resources, to help us prove that our solution was worth the investment.

Fast forward to today and not only have we kept all but one of our customers—one ceased operations—but we have never had a catastrophic facility loss start in an area we protect. Additionally, we have been awarded a utility patent for our solution; won a Gold Edison Award for industrial innovation; have been included in several National Fire Protection Association (NFPA) codes; secured many variances for industrial uses that replace traditional sprinkler systems; have been highlighted in NFPA’s Fire Protection Handbook; and are in the final stage of being accepted for two insurance industry certifications that will provide us the credibility needed for our solution to be accepted by the fire industry.

The Fire Rover Performance Scorecard

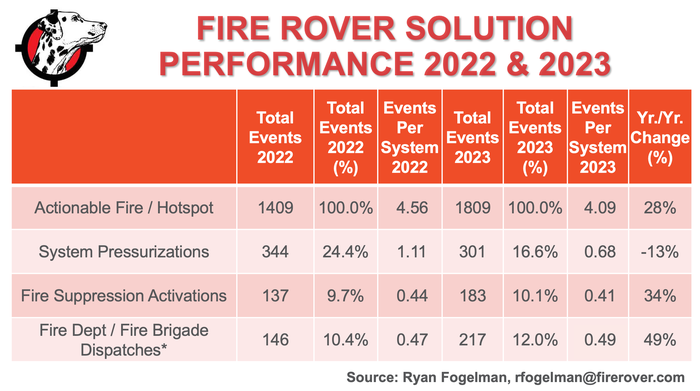

So, let’s dig into the numbers. If you follow my data and reports, you will see we adjusted the data to now include “Actionable Fire/Hotspot.” These are the verified fire hazards that our Fire Rover agents encounter during their main monitoring. Think along the lines of a loader pulling a lithium-ion battery out of a pile or an auto shredder residue pile. The main difference between our solution and any other solution on the market is we are the only ones looking at every piece of hay to find the needle in the haystack. Our agents look at thousands of straws of hay (false triggers like machinery and equipment) to find the needles (Actionable Fire Events). In 2022, we experienced 1,409 Actionable Fire/Hotspot events, which increased to 1,809 events in 2023. This makes sense based on the number of our installations increasing from an average in the 300s to an average in the 400s.

“System Pressurizations” are every time our Fire Rover agent brings water to our strategically placed nozzles. You can see this number has decreased year over year. This makes sense based on the fact that our agents have gotten better at knowing when to prepare for combat. The fact is there are consequences for our clients when we fill a “dry” system with water. In our Fire Rover box systems, it might waste some of our supply as we have to purge the suppressant if it is not used so it doesn’t freeze. Similarly, our continuous flow solution utilizes water from the city or an outside tower, so the pipes must be drained after shooting. As a company, we have worked extremely hard to learn from our extensive experience to be as efficient as possible with our clients’ resources, especially those that can lead to any disruption in their business operations.

Now we get to the fun part: “Activations.” These are exactly what they sound like. Our agent is shooting one of our nozzles to suppress an active fire. This number accounts for about 10% of our incidents and has remained relatively consistent year over year.

As I have said in my reported data from the beginning, the first two years are really a benchmark, but we can start to identify trends in year three and continue from there.

The final key performance indicator is when we dispatch the fire department or formal fire brigade to our clients’ operations. This number increased by almost 50% year over year and 2% in total events from 2022 to 2023. We have a degree of discretion as to whether an event will require the fire professionals to arrive on the scene. Working with our clients, we have been determined that a more aggressive dispatch approach is warranted to keep workers safe during an active fire and in the overhaul/clean-up phase.

The other number that deserves explanation is the number of dispatches compared to the number of sprays or suppressions. We offer our customers detection-only solutions at their operations through our OnWatch Mobile Landfill Detection Unit and our Fire Watch Replacement solution where the identification of a fire hazard results in an immediate dispatch to the fire department. Additionally, we commonly encountered incidents where our detection equipment identifies fire incidents that are out of our nozzles’ range.

Why Do We Share These Numbers?

Why am I sharing this data? Honestly, the biggest issues in the waste and recycling occupancy are a lack of insurance options, increasing premiums and the overarching decrease in appetite for the risk we see in the industry. I believe the only way to change the insurer’s opinion is by showing them we are investing in solving the problem. I will say it repeatedly, but our system virtually eliminates the risk of catastrophic loss due to fire. In addition, almost all facilities are back up and running within hours, with very few instances of damage requiring repair. Insurance companies need to understand the mitigation of fire risk and that it is manageable with an investment in our solution and operational best practices. In the U.S. and Canada, a commitment has been made that I believe will result in FEWER reported fire incidents in the future, even with MORE fire hazards entering our waste and recycling streams over the coming years.

Conclusion

Again, I want to thank our early adapters who believed in our solution from the beginning. We are seeing so many other supposed “AI Systems” that promise to work in the real world and fail for so many different reasons due to false alarms, false deluges, spraying into employees and/or equipment, and so many other issues when dealing with “active” situations. FM has classified our solution as the first “Smart Monitor” due to our unique layering approach that allows for early detection and safe and controlled suppression of any fire hazard that we come across. Fortunately, we are now in the process of replacing some of these systems across the globe and continue to work to help the waste and recycling industry stay safe and operate continuously with little to no downtime, as shown in our 2022 and 2023 scorecards.

The work on the “7th Annual Reported Waste & Recycling Facility Fires Report” continues. I have spent the year compiling the data, and now it is time to consolidate and analyze it to see what new insights we have gained over the years. This year's report will be sure to include a deeper dive into the Fire Rover performance scorecard, as well as the latest death/injury data, which shows that more than 9% of the 373 fire incidents we incurred in 2023 resulted in an injury or death; a state-by-state (province-by-province) analysis of how your locality is performing from a tonnage and site number perspective; and much more data and information. I am hosting a webinar to review my findings on March 12th at 1:00 PM EST. You can reserve your spot at https://events.teams.microsoft.com/event/8eb866a5-3b59-4904-9cd6-801fb1d4d74b@1148408c-88bc-40b6-a499-6a1c80a8bcf4, space is limited. If you would like to reserve a digital copy of my report upon release, you can enter your information at https://lnkd.in/dgAX9Ze or subscribe to my LinkedIn 🔥 Fire Safety Report 🔥 newsletter at https://lnkd.in/gjwNpSph.

About the Author

You May Also Like