Entrepreneurs Spin New Packaging Innovations

Five entrepreneurs and startups have earned recognition for their packaging innovations by the Sustainable Packaging Coalition (SPC). SPC’s Protective Packaging Design Challenge was done in partnership with Ubuntoo, Closed Loop Partners, and the Retail Innovation Center.

Waste360 talked to three of the finalists about their inventions: Flexi-Hex, Cruz Foam, and Returnity and would also like to congratulate the remaining sustainable packaging champions earning this special recognition: TemperPack (ClimaCell) and Ecovative Design (Mushroom Packaging).

Finalist Flexi-Hex, based in Cornwall, U.K., develops compostable packaging that rivals expanded polystyrene foam, inflatable air sacks and bubble wrap. The company’s core technology was designed for multiple applications, with a few being beverage, photo frame and furniture packaging.

The packaging is 100 percent recycled content that breaks down in about six weeks, confirmed through Flexi-Hex’s self-testing.

It’s a paper honeycomb sleeve that forms around shapes, and as it opens it expands around objects, so it takes up little space, explains Sam Boex, director of Flexi-Hex.

The sleeve can expand up to 35 times wider than its compressed form.

In the case of bottles, 7,200 sleeves will fit on a single pallet.

“Honeycomb paper is a standard packaging material to create rigid panels. But very few considered using it for its flexibility,” says Boex. By capitalizing on this feature, the company has not only been able to make a space-saving product, but a more protective one.

“If the package was dropped, the impact spreads across the entire package since the material forms to, and wraps entirely around, its contents, so there’s less chance of breakage during shipping,” he explains.

Flexi-Hex first launched its honeycomb sleeves in the sports industry and now sells to the surfboard industry in 19 countries. It sells in the U.K. to beverage companies who sell direct to consumers and to packaging distributors as an e-commerce solution.

The biggest challenge has been developing a product that dovetails into clients’ existing operations and needs.

“The packaging process has to be at least as fast as existing processes. And it has to fit into those processes. For instance, it must work within their production space. Or with drink units that must be packaged at a certain weight and size to easily go through the courier system,” Boex says.

Future plans are to bring beverage packaging into U.S. markets. And currently Flexi-Hex is working with global tissue manufacturer Seaman Paper to develop products for cosmetic and electronic markets.

“It’s a scalable business with a lot of raw material available from factories globally. So we have capabilities to expand quickly. We want to create a recognizable global packaging brand over the next five years or so,” says Boex.

Returnity Innovations, headquartered in Brooklyn, NY, manufactures customized, reusable shipping and delivery packaging out of recycled polyethylene terephthalate (PET) that is shown to be more durable than cardboard.

Its bags and boxes, which are guaranteed to be usable 40 times, can fold when returned empty, saving on cost and resources. They reduce packaging costs more than 50 percent and emissions more than 60 percent, according to Mike Newman, CEO of Returnity Innovations.

“The need to solve for both performance and cost ultimately led us to default to the use of recycled PET. It is light-weight, durable, recyclable, waterproof, and allows for a premium look and feel,” he says.

A few of Returnity’s clients are fashion rental company Rent the Runway; Happy Returns who developed easy merchandise return processes; and For Days who sells t-shirts, takes them back and makes them into new t-shirts. Returnity is also working with e-commerce companies to test and deploy systems that would allow an economic switch to reusable packaging.

“In our early days we thought that product-design was the pathway to success. The reality is that logistics systems dictate what it takes to be a successful package. Since then, we’ve built our development toolkit, which includes features such as label systems, tamper-evidence options, and flexibility in how products collapse. This has enabled us to package everything from apparel to wine to sofas, and across a variety of shipping models,” says Newman.

“We have made significant progress but don’t think we will ever be ‘done.’ We are constantly finding ways to make our packaging lighter, easier to use, and easier to recycle,” he says.

Still, last year was a big one; the company grew nearly 700 percent and displaced six million shipments in single-use packaging by the summer of 2019.

“In 2020 we’ve already passed our revenue from last year and believe our relationships with some of the biggest retailers in the world will allow us to transform what shipping packaging can and should be over the next few years,” says Newman.

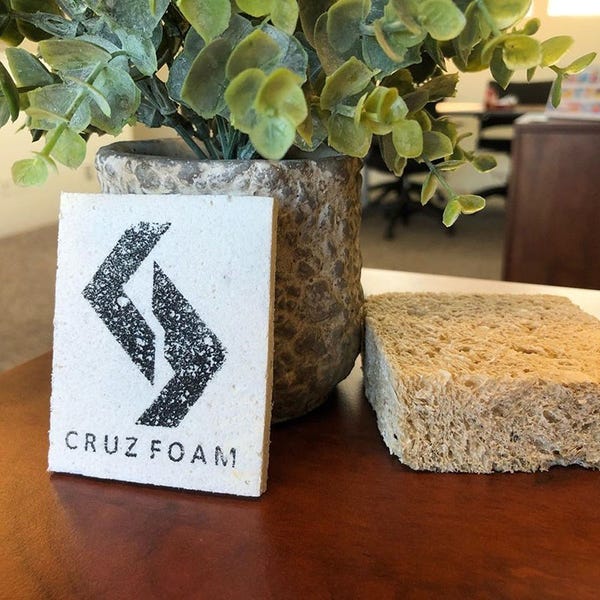

Cruz Foam, based in Santa Cruz, Calif., creates several compostable packaging materials using shellfish waste and a biopolymer that’s inside the shell waste to make a naturally sourced foam. It’s intended to serve as packaging for electronics, furniture and other consumer goods. So far the company has done five proof of pilot tests for manufacturers of electronics and other consumer goods.

The biobased polymer in the shellfish, chitin, comes from renewable waste and has high-strength-to weight ratio.

“So it’s strong and light. And it’s a good composting material because it retains nitrogen in soil, so it helps with the growth of plants, thus increasing its ability to aid in composting,” says John Felts, CEO Cruz Foam.

The company is discussing partnerships to scale for early stage commercial production. The goal is to roll to market by the end of 2020.

The business has done piloting for a Fortune 500 beverage company, creating packaging designed to be able to ship e-commerce products. It’s done pilot packaging for Ford Automotive and other unnamed companies and is in discussion with more potential customers, says Felts.

Cruz Foam dissolves the biopolymer in a water-based solution with no harsh chemicals or volatile organic compounds. This process breaks material down into a viscous liquid, which expands and hardens into a solid structure, just as occurs when foam is made.

“So you get a structural foam with mechanical properties like durability at high impact due to its strength. And you get high insulative properties. Further, we are using renewable waste rather than taking a finite resource. And it’s a nontoxic process.

So at the end of the day, we have high-value mechanical properties. We can incorporate other waste streams like recycled paper. And our material breaks down in soil in three months,” says Felts.

About the Author

You May Also Like