As we prepare for the cooler months ahead, it’s time to start thinking about fire safety and the precautions necessary to keep waste and recycling workers and facilities safe. Do you have the right equipment? Are your employees trained to respond to potential fire incidents? Are your customers aware of which materials you can and cannot accept?

I spoke with one operator, FCC Environmental Services, to find out how it's approaching fire safety and investing in the proper equipment and technology to keep its facilities and employees safe from hazardous materials and potential fires.

September 2021 Fire Data

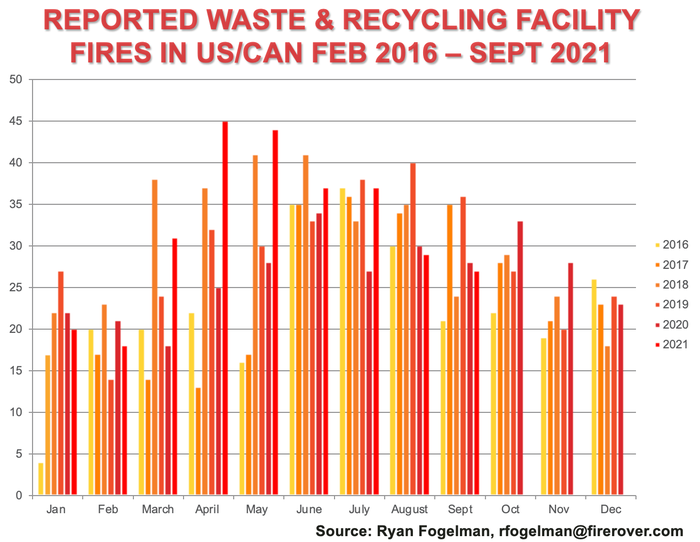

In September, we encountered 27 reported fire incidents at our waste and recycling facilities in the U.S. and Canada. Of these reported incidents, 12 occurred at waste, paper and plastic operations, 11 occurred at scrap metal operations, two occurred at construction and demolition operations and two occurred at organics facilities. At Fire Rover’s 250-plus client operations, we responded to 69 fire incidents in September to go along with the 74 from April, 88 from May, 77 in June, 88 in July and 92 in August.

This September was in line with historically reported waste and recycling facility fires in the U.S. and Canada. For those not affected, there is finally a respite to the hot summer months.

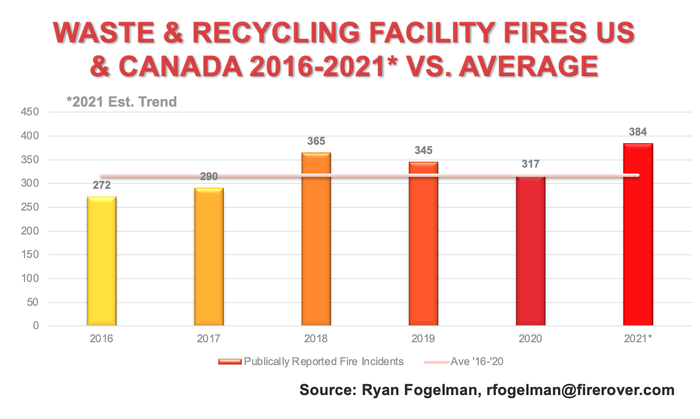

Looking ahead to the rest of the year, we are unfortunately still on pace for 2021 to be the worst year for publicly reported fire incidents since I began tracking these fires in 2016. I can assure you that I have my eye on this number and look forward to the end of the year where I consolidate the 2021 data and insight for the next “Waste & Recycling Facility Fires Annual Report.”

A Conversation with Andrea “Passionista” Rodriguez-Pinero

It seems like yesterday that I started focusing on the waste and recycling industry. Since I attended my first conference in 2015, I have been extremely fortunate to meet and get to know some amazing, talented individuals. One of those individuals is the person I interviewed this month, Andrea Rodriquez-Pinero, director of engineering at FCC Environmental Services.

When I first met Rodriquez-Pinero in 2017, I could instantly tell that she was cut from a unique cloth. She is a passionate “executer” who leaves no stone unturned when it comes to designing and developing FCC’s world-class recycling facilities.

Rodriquez-Pinero hails from Madrid, Spain, and has a bachelor’s degree in chemical engineering from Universidad Rey Juan Carlos as well as a master’s degree in industrial management.

When she first began her career, she tried her hand working as a chemical trader but quickly discovered she preferred the operational side of the business more. So, in 2010, she took a job working as a project engineer developing wastewater treatment plants. In this role, she found her initial passion for helping protect the world.

A few years later, in 2014, she made the switch to the solid waste and recycling industry, accepting a role to help build the recycling business unit of FCC in the U.S. when the company was awarded the service contract for the city of Dallas.

The Dallas materials recovery facility (MRF) earned the National Waste & Recycling Association’s (NWRA) Recycling Facility of the Year Award in 2017, and FCC’s Houston MRF, built shortly after the Dallas MRF, was honored with NWRA’s Recycling Facility of the Year Award in 2020.

Those accomplishments, along with many others, have proven that Rodriquez-Pinero is skilled at designing MRFs, but she also is skilled at operating MRFs and understanding their innerworkings.

When it comes to designing MRFs, Rodriquez-Pinero suggests spending some time operating one first so you can understand the ins and outs of this type of operation, equipment needs for growing and changing volumes and the challenges and opportunities that come with handling recyclables.

“I like to think that the work we do impacts the lives of so many people,” she says. “Not a lot of people realize how important the service of waste management is in their lives. But could you imagine not having your trash and recycling collected for weeks?”

To further understand FCC’s operations and Rodriquez-Pinero’s viewpoint on technology and fire safety, I sat down with her for a quick Q&A.

Ryan Fogelman: What role does technology play in the waste and recycling industry?

Rodriguez-Pinero: With all the material changes we are seeing from the “Amazon Effect” and the increase in lightweight plastic packaging, MRFs need to be very flexible and versatile so they can adapt to the changing waste and recycling streams.

New and improved technologies, including artificial intelligence (AI), robotics, vision recognition in optical sorters, control systems, etc., will play a key role in MRFs of the future. It is a game changer for us to know our material composition at any time so we can adjust the system accordingly. AI can also be used to check the quality of bales or to develop educational tools to help the community reduce contamination.

At FCC, we have built an educational center within our facility to provide training and to educate children and adults about best practices for sustainability and recycling. These tours are offered in both Dallas and Houston.

Ryan Fogelman: What is your approach to fire safety?

Rodriguez-Pinero: In addition to installing the latest technology including fire sprinkler systems, thermal cameras, ABC and water fire extinguishers, we were early adaptors of the Fire Rover, which adds an additional and critical layer to our fire mitigation plan. These investments are extremely important and help protect our employees and facility from the hazards we see in the materials we receive.

At FCC, we take the safety of our employees very seriously. All employees are trained on the best practices of proper material segregation, the PASS [pull, aim, squeeze and sweep] method for fire extinguisher use and “Fire Watch” activities in case one of our many fire systems is down for mechanical or maintenance issues.

We also stay diligent in housekeeping to avoid dust and material collecting in areas that could pose a fire danger or egress issue; maintain compliance in routine facility inspection thus improving our safety culture and ensuring we have no fire potential in our facility; and conduct random fire drills with educational training throughout the drill so employees understand there are multiple ways out of the facility.

Ryan Fogelman: What role does the community play in these fires?

Rodriguez-Pinero: We consistently work with the public to educate them on what can and cannot be recycled and what materials we can accept at our facility. If the wrong item is placed into the recycled bin, it may end up causing a fire.

We believe in investing in education because education is key to reducing contamination and items that shouldn’t end up in the recycling bin, such as lithium-ion batteries or propane tanks that can cause fires. The proper disposal of each material is key to reducing fires, increasing the safety of our employees and increasing the landfill diversion rates.

Conclusion

After my conversation with Rodriguez-Pinero, one thing is apparent to me: she is extremely passionate about having the best-designed and best-running facilities, but she also understands the big picture of how recycling fits into the world on a macro level.

I always say that there is an inherent risk of fires in our waste and recycling streams, but good operators will always have less fires than bad operators. Can we educate or operate our way out of the fire hazards we face as an industry? No, but we can keep trying, learning, educating and implementing best practices as we continue to go down this path.

As Rodriguez-Pinero so clearly asked me, “Can you imagine not having your trash and recycling collected for weeks?” Truth be told, I could not, and I bet you couldn’t either. So, we need to find solutions to our problems because we are an essential industry that can’t just pack up and go home when times get tough. It’s time to put our heads back in the game and start working smarter and safer.

Ryan Fogelman, JD/MBA, is vice president of strategic partnerships for Fire Rover. He is focused on bringing innovative safety solutions to market, and two of his solutions have won the distinguished Edison Innovation Award for Industrial Safety and Consumer Products. He has been compiling and publishing the “Reported Waste & Recycling Facility Fires In The US/CAN” since February 2016 and the “Waste & Recycling Facility Fires Annual Report.” Fogelman speaks regularly on the topic of the scope of fire problems facing the waste and recycling industries, detection solutions, proper fire planning and early-stage fire risk mitigation. Additionally, Fogelman is on the National Fire Protection Association’s Technical Committee for Hazard Materials. (Connect with Ryan on LinkedIn at https://www.linkedin.com/in/ryanjayfogelman or email at [email protected])

About the Author(s)

You May Also Like