An executive summary of the “2019 Annual Waste & Recycling Facility Fire Report.”

The number of reported waste and recycling facility fires that occurred in the U.S. and Canada in the month of January totaled 23 incidents. This was coming off a low of 14 fire incidents that we experienced last year in February. The fire incidents this month consisted of 10 at scrap metal facilities, seven at waste processing facilities, four at organics facilities and two at rubber recycling operations.

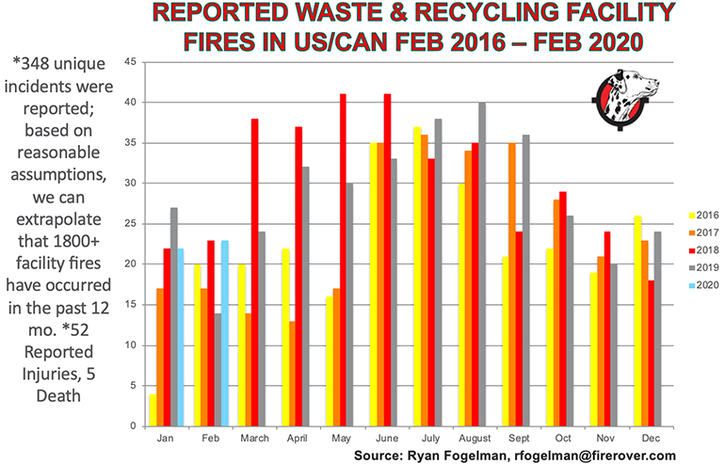

During the past 12 months, the waste and recycling industry has experienced 348 reported facility fires in the U.S. and Canada. Additionally, we incurred 52 reported injuries and five deaths that can be either directly or indirectly attributed to these fire incidents. Based on reasonable assumptions, we can extrapolate that 1,800-plus facility fires have occurred during that time, which, based on the number of facilities reported by the Environmental Research & Education Foundation (EREF), is more 40 percent of the industry. I define “reported facility fires” as any fire that has been reported by the media that occurs at a waste or recycling facility in the U.S. and Canada. Typically, the fires that are reported by the media are larger fires that require fire professionals to arrive on scene and where there are affects that the public can witness.

For the past three years, I have worked hard to consolidate the prior year’s data, analyze it and compare the data to prior years’ data, which I published in a report titled “2019 Annual Waste & Recycling Facility Fire for the U.S./Canada.” That said, I have provided the executive summary in this month’s article, which I hope readers find valuable:

2019 Annual Waste & Recycling Facility Fire Report Executive Summary

As we close out the old and enter a new decade, I have developed some clarity around the fire problem that we face in the waste and recycling industry. In the last decade, we were caught off guard, but heading into the 2020s, we are in a different position. We better understand the risks that we face and are actively seeking and implementing solutions to the problem. When we launched Fire Rover in 2015, which was centered around fires, we had a front row seat in the scrap metal recycling facilities we provided security for. None of us understood the hazards and true scope of the problem we were facing.

We had experienced traditional hazards in waste and recycling from propane tanks, chemicals, forklifts and more, but none of us were prepared for the dangers that the wave of lithium-ion batteries brought to our operations. As I sought to find the true depth of the problem, we were all witnesses—both directly and indirectly—to the true extent of the personal storage revolution.

Fast forward to 2020, and I feel that we are in a much better place. Most organizations and associations have started to address the problem. Individual companies have addressed the problem through fire protection plans, employee training, public education and investments in fire detection and elimination technologies. Along with organization initiatives, 2019 has brought focus from industry associations, each of which have some level of response to the fire issues. One example is EREF’s “Assessment of Fires at MRFs & Scrap Yards” survey that seeks to identify “The Causes & Impacts of Recycling Facility Fires” in the U.S. and Canada. The research project is in partnership with the National Waste & Recycling Association, the Institute of Scrap Recycling Industries (ISRI) and the Solid Waste Association of North America (SWANA).

In addition, ISRI sponsored “A Guide to Creating a Fire Prevention & Management Plan” that was released this month and is focused on how to plan for scrap metal fire. In addition, SWANA did a report last year focused on fires in waste-to-energy facilities.

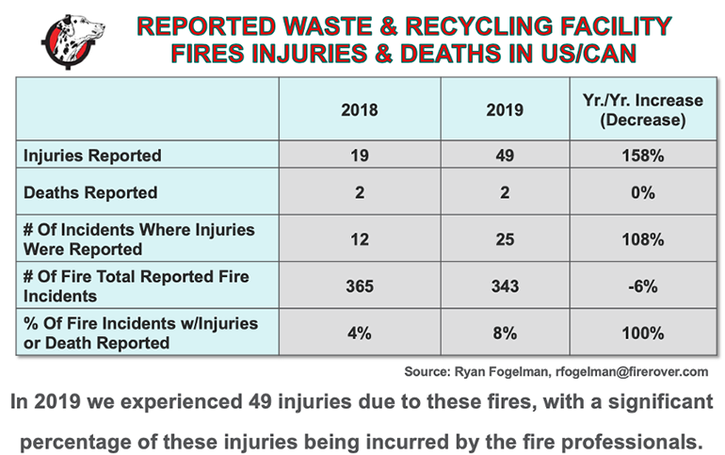

With all the positive momentum, we are still a long way from solving the fire issues we face. In 2019, we experienced a rash of reported injuries both directly and indirectly due to these fire incidents.

Most of these injuries were “heat stroke” experienced by the dedicated fire professionals fighting these fires in the sweltering heat of summer. In addition, we saw insurance companies raising premiums and even walking away from covering our industry’s properties due to the growth in shredder and lithium-ion claims they were experiencing, which is outlined further in the “Consequences” section of this report.

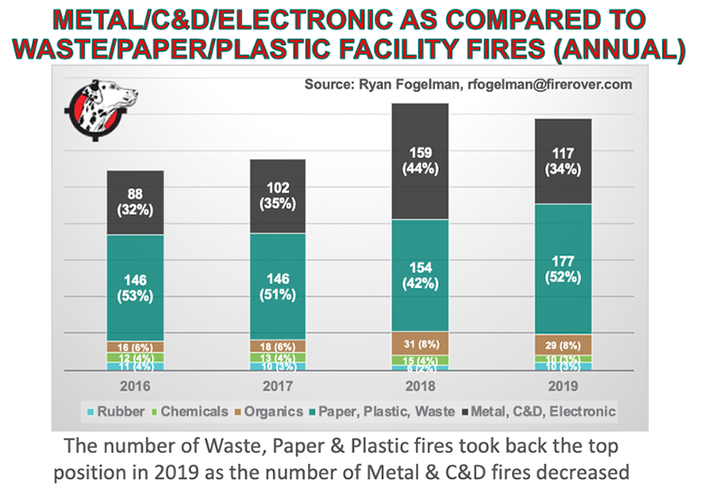

Anyone who researches and compiles data knows that sometimes you face a “moment of clarity” where you start to see the data developing in a way that strikes a chord. This moment hit me earlier in the year when I was working on research and having a hard time classifying the “cause” of a fire. I started to see waste facilities that reported a fire that clearly started in their paper pile, but since it was a waste facility, it was classified into the “waste” category. The eureka moment hit me that waste, paper and plastic could be consolidated into one bucket, and metal, construction and demolition (C&D) debris and electronic scrap could be consolidated into another bucket. I kept organics, chemicals and rubber in their own distinct buckets. See the graph of their percentages of total fires incidents below:

The purpose I see for this is very simple: the fire incidents we see due to these types of fires are different. Materials recovery facilities (MRFs) that process waste, paper and plastics are typically comingled, and especially with the trend toward single stream recycling, we see more and more hazards showing up either accidently or due to miseducation. Think someone placing an old iPhone in the blue office receptacle for recycling paper. Or someone placing a greeting card in the trash or in a paper recycling bin not realizing there is a battery in the load. The fire incidents we see are similar and can be consolidated for the purpose of understanding the scope of the problem and solving the problem.

With metal, C&D and electronic recycling, there is a hazard that should be known to the operator. For example, when a car gets into a car accident, there are a number of potential hidden dangers like vape pens, earbuds or phones hidden in the seat cushions or under the seat. The same with C&D and electronics—if the material comes from a building that burned or pieces of equipment, there are hidden dangers that are part of the pre-processing of the material. I have received pretty good feedback about these assumptions, but I also realize that some might disagree, which is why I still plan to provide the data both in the consolidated buckets and their individual buckets.

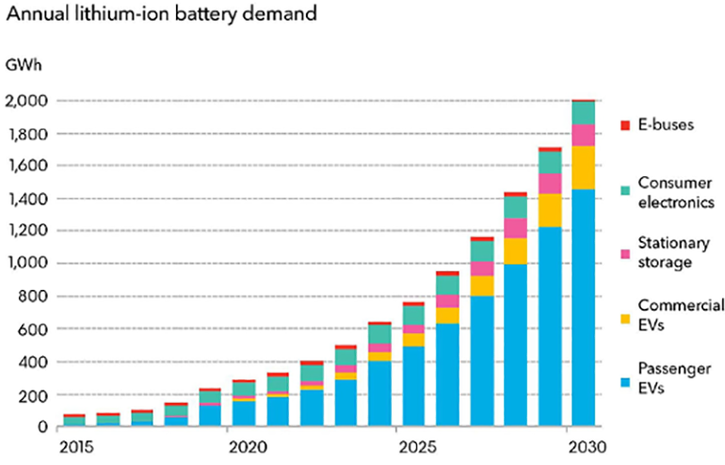

Now, the biggest issue I see facing the industry is the growing number of lithium-ion batteries being forecasted for personal storage over the next decade.

According to an article by Matt Bohlsen that was published in August 2019 in Seeking Alpha, “No matter which way you look at it, lithium-ion (Li-ion) battery demand is set to surge about tenfold between 2018 and 2030 (see BNEF chart below)."

Another way to get a feel is the Benchmark Minerals megafactory data, which as of a July 5, 2019, Tweet: "Assessment published at 1,956.6GWh [gigawatt hours] capacity by 2028, increase of 5.25%, now tracking 91 plants." The 91 number was three back in Q1 2015, showing how much megafactory demand has advanced in just four years. (Source: BloombergNEF)

The fact is no matter how hopeful we are that there is some new water-based, non-flammable portable energy storage solution coming down the pipeline, this hope is not based in reality. The reality is that lithium-ion batteries are king based on their price, manufacturing infrastructure and amount of power they can provide in a relatively small footprint. Even if a new solution is developed, the time it will take for the world to commercialize would be years.

I have one of the best jobs and one of the worst jobs a person can have. I have spent the past five years in an industry in which we cannot do without (waste) or should not do without (recycling). We are in the heart of an epidemic that is causing havoc in our operations. From my perspective, we have made it through the hardest part, which was getting our arms around the initial and continued scope of the problem. The problem is not going away, but the industry has been stepping up by working together, educating, executing and investing in strategies and solutions that are mitigating both the traditional fire risks as well as the onslaught of fire risks we are experiencing through lithium-ion batteries.

My passionate belief is that “safety should not know competition,” and we, as an industry, should continue our efforts to find a solution to the fire problem we will face. As Homer Simpson so artfully said, “We are the cause and solution to all of our problems.” Although he was referring to “beer” as the culprit, I believe that all of us working in concert, staying in touch with the everchanging scope of the problem, while understanding the consequences and developing solutions both on the front and back end, will ultimately result in less fire incidents in our waste and recycling facilities, even with the growing hazards we face.

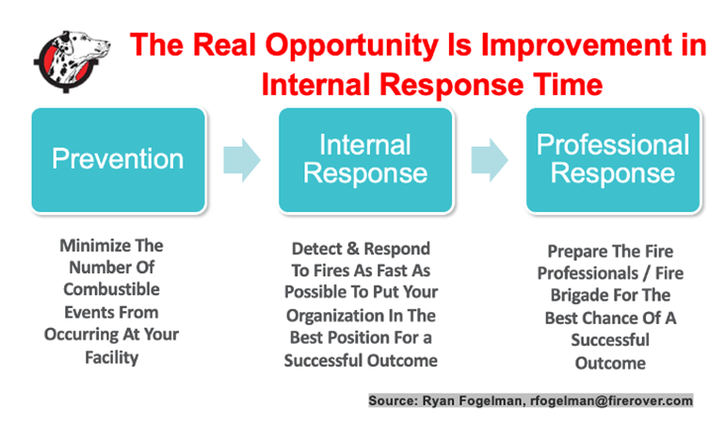

The fact is that having fires is inherent in our operations. Having fires is OK as long as you can catch and safely suppress them before they become a major incident. There are several industries that have inherent fire risk in their operations. These industries typically have some sort of protection that makes this risk manageable. The approach that I recommend to my clients when asked for advice on how to lower their operations risk profile is as follows:

Prevention. The most important part of fire prevention is to develop a plan of attack. Prevention is the basic blocking and tackling and should include all components of minimizing the potential number of events that can occur at your facility.

Internal Response. This is key. I typically tell folks that early detection is the key to catching and mitigating a fire early. The goal is not just to catch a fire when there are flames but to understand that there are situations where hot spots can be cooled before they flame. The goal is to set the trip wire as early in the process as possible. This can be done through top-grade thermal detection in combination with smoke and other analytics and, most importantly, a highly trained agent able to weed through false positives in an effort to fight only the incidents that need fighting.

Professional Response. Another extremely important part of the internal response is to prepare the professional response. Investing in having the proper equipment for the fire department onsite can be a huge timesaver. Even going as far as having attached and rollout hoses so the firefighters can immediately start applying suppressant to the affected area can make a huge difference. Most importantly, having an active relationship with your local fire department is imperative.

Ultimately, as an industry, we need to make a choice. We need to focus on dealing with the inherent risk of fires we encounter by developing processes and solutions that catch and suppress fires as quickly as possible. We spend so much of our time and resources on educating the public of the hazards of improper recycling in an effort to get these hazards out of the recycling stream. The issue that we face is that education only focuses on one piece of the problem. We see these hazards in construction and demolition, metal recycling, municipal solid waste processing and more. Don’t get me wrong, educating the public on their unintended effects is important, but in my opinion, we can get more bang for our buck investing in fire prevention plans, safety processes and technologies that truly mitigate the fire risks before they have a chance to become a major incident.

We need to keep up the fight. The day will come where the number of fire incidents in our facilities, especially the major fire incidents, will catch up to the danger, and we will see these reported numbers steadily decreasing. For those of you out there who are contributing to the solution through your company, organization or yourself, I appreciate your continued efforts.

Ryan Fogelman, JD/MBA, is vice president of strategic partnerships for Fire Rover. He is focused on bringing innovative safety solutions to market. He has been compiling and publishing the “The Reported Waste & Recycling Facility Fire In The US/CAN” since February 2016 and the “Waste & Recycling Facility Fire Annual Report.” Fogelman speaks regularly on the topic of the scope of fire problems facing the waste and recycling industries, detection solutions, proper fire planning and early-stage fire risk mitigation.

About the Author(s)

You May Also Like