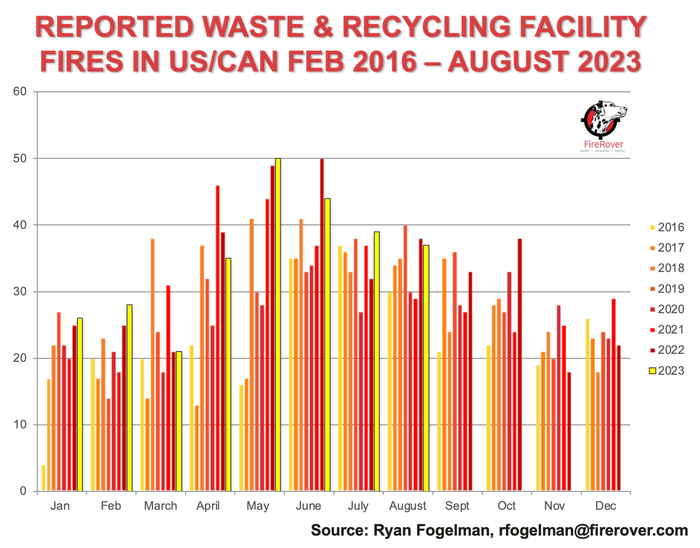

Lithium-ion batteries seem to be all we talk about and for good reason, as their inclusion in the waste and recycling streams has clearly had a negative effect on fires in our operations. But the truth is batteries are only responsible for half of these fires. Just look at the summertime spike we have witnessed each summer since I began consolidating reported fires.

Lithium-ion batteries seem to be all we talk about and for good reason, as their inclusion in the waste and recycling streams has clearly had a negative effect on fires in our operations. But the truth is batteries are only responsible for half of these fires. Just look at the summertime spike we have witnessed each summer since I began consolidating reported fires.

One could argue that lithium battery fires should stay consistent all year round and probably not necessarily get worse during the summer months when the weather is hot and dry. One could also say that we see more of hazards such as gasoline, paint thinner, fireworks, propane tanks, pool chemicals and hot barbeque briquettes in those months due to summer outdoor activities. As we continue educating the public on the dangers of lithium-ion batteries, we must also remember to educate the public, including businesses, on other hazards that are accidentally or deliberately placed in bins.

I, along with several associations, operators, fire departments and others, have been getting the word out that the public needs to properly dispose of their waste and recyclables. We, the public, cause “bincidents” daily by knowingly or unknowingly placing hazards in our trash and recycling bins. These actions that have been inundating our waste and recycling streams are causing fires in trucks, on tip floors, in sorting equipment and at landfills. Therefore, waste and recycling operators are in a daily battle to ensure they do not let hazards enter their operations.

With that said, as a society, we take for granted that we might not know any better, but the fact is a number of these hazards are coming from large entities, and as I will highlight in this article, even from some battery manufacturers. As most operators will tell you, it is not always easy to know which customers are sending hazards into the waste stream, but when they do know, actions need to be taken to deal with the problem and entities must take responsibility for the fire, damage and destruction that their hazards cause. In this article I will share the reality of this practice and how it affects the waste and recycling operators, both small and large.

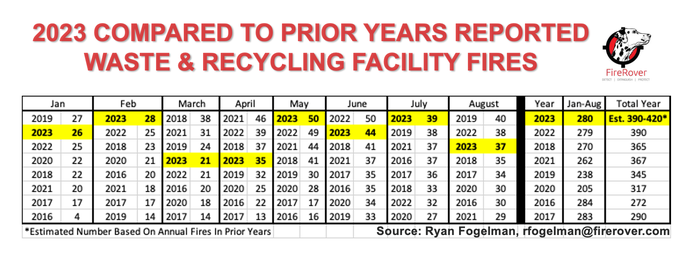

August 2023 Fire Data

In August, we encountered 37 publicly reported fire incidents at our waste and recycling facilities. Of those incidents, 17 occurred in waste, paper and plastic facilities, 13 occurred at scrap metal recycling facilities, four occurred at organics sites and one each occurred at an electronics recycling operation, a rubber recycling operation and a construction and demolition (C&D) operation. At Fire Rover, we responded to 400-plus hot spots and/or fire incidents at our clients’ facilities.

As you can see from the data, we were fortunate to experience a slight reprieve in July last year, but the relentless heat, along with the continuing increase of lithium-ion batteries in our waste stream, has made 2023 a year for the record books.

In the first eight months of this year, we have seen records, or close to records, in five of the eight months and are trending to either meet or exceed the record number of fires we experienced last year. No matter how 2023 turns out, it is clear this issue is not going away anytime soon. Also, of the 280 fires so far this year, only a few facilities were equipped with our Fire Rover solution, and none of those facilities had a “major or catastrophic” loss. So, the fact is the number of fire incidents is increasing, even as we continue to grow the number of facilities we protect, which at today’s count is 500-plus facilities across the U.S. and Canada.

Tracking Where the Fire Hazards Come From is Not an Easy Task

Last month, a person or business improperly disposed of a dozen air lighters. Not shocking, they lit on the transfer station tipping floor, spread to other items in the municipal solid waste pile and started a major fire incident. Whether the lighters were thrown away deliberately or accidentally, there needs to be consequences to stop these types of events from occuring.

It is hard to argue that anyone in the country should know not to dispose of 24 full lighters in a garbage can. You cannot bring lighters on airplanes because of the dangers. So, clearly, they shouldn’t be thrown away. But we are all so used to dropping anything in our magical waste bin because we haven’t really faced any consequences for throwing away certain items. Am I suggesting we lock these people up? Absolutely not. But I am suggesting we audit some of these incidents so we can identify the behavior and address it. Maybe we issue a fine for the second or third offense or explore another proactive “smack on the hand” to get people to think before they throw unsafe material like lighters, gasoline, paint thinner, fireworks, vapes, propane tanks, old paint, pool chemicals, hot barbeque briquettes and other potential fire dangers into the waste stream. By eliminating these potential hazards, we can better protect employees, facilities and the equipment of our critical waste infrastructure.

There are Places to Properly Recycle and Dispose of all Material

In the U.S. and Canada, there are proper channels for material to be discarded. But it typically comes down to a cost/benefit analysis. If you have to get rid of a certain type of material, whether it be spoiled food, lithium-ion battery components or chemicals, there are places to properly dispose of this material. But some choose to dispose of this material in alleys or waterways. This is illegal, and there are and should be consequences for the “bad actors” who should know better.

An example of this occurred in May 2022 in New Jersey, where a New York man rented a standard trash bin and dumped more than 9,000 pounds of pressurized aerosol can containers of dry shampoo. “This careless action resulted in a large quantity of highly flammable materials going into the waste stream, effectively sending the workers at this facility in Elizabeth a firebomb that was waiting to go off,” said state Attorney General Matthew J. Platkin in a Union Daily Voice article. “And when it did, it had lethal consequences.”

The fire grew to a five-alarm fire that burned through much of the evening and led to the evacuation of nearby homes and businesses, as well as the death of an employee.

In response to this incident, Derek Nececkas, interim head of the state Division of Criminal Justice, pledged to “hold polluters accountable, particularly when their disregard for dumping laws leads to an outcome as egregious as this—a fatal, massive blaze in one of New Jersey’s most populous urban areas.”

While incidents like this occur due to careless actions, most operators set up to accept hazardous materials work to ensure their customers can safely and properly dispose of these hazards properly.

One operator doing just that is the Lycoming County Landfill in Montgomery, Pennsylvania. In a Williamsport Sun-Gazette article, Lauren Strausser, recycling coordinator at the Lycoming County Landfill, shared the landfill also has a place for collecting a small amount of batteries. “We’ll package that up and recycle it,” she explained. “We have a collection over by the self-dump here at the landfill for lead acid car batteries. So, we have a home for that. But what we don’t have is a home for a bulk amount. We have had people come with buckets full of batteries that they’ve stored for years and years, which you should not do because that is very dangerous.”

The reality is the onslaught of electronic waste has changed the game for all operators globally. Maria Jensen from Minnesota Reformer said it best: “When it comes to e-waste, our goal should be nothing short of 100% proper collection. Although e-waste is a curse is for our solid waste folks, it is valuable to recyclers. E-waste recyclers are experts at extracting valuable material like gold, palladium, platinum, silver, lithium, nickel and copper from our old electronics.”

What Can Happen When a Customer Doesn’t Comply?

This brings me to share an extremely important incident that occurred and ended in a catastrophic loss due to a fire at an operator’s business that allegedly started due to the carelessness of a customer. Georgia-based Metro Site is run by Scott and Christy Ledford, who got into the C&D business after owning both a hauling and construction company and seeing the number of loads being sent directly to the landfill. They saw a void in local C&D operations and decided to invest a significant amount of money to bring that capability to a small but fast-growing part of the world.

After he started his operation, he learned a lot about building operational efficiencies and utilizing automation. But on July 14, this all changed after his facility had a catastrophic loss due to fires allegedly caused by one of the large lithium-ion battery manufacturers located in his community. According to Ledford, whom I spoke with directly, SK Battery America was sending Metro Site 30 loads a day that included films, plastic pallets and corrugated boxes, but sometimes the company “accidentally” discarded battery packs into the material that Ledford’s team needed to separate out and call SK to retrieve.

According to Ledford, SK didn’t have many options for its material because the local landfills were not willing to accept the material directly due to the risk of these battery packs finding a way into their loads. Those “accidental” batteries had caused fires before. In fact, SK’s batteries had caused numerous fires at Metro Site in the prior year before the July incident.

During a meeting January of 2023 to discuss requirements for removing the battery hazards from their recycling loads, Ledford said SK agreed to several steps that included creating a “battery watch” at its facility so no batteries could “accidentally” get into the material headed for Metro. Ledford also received assurances from SK that it would be monetarily responsible for any downtime that occurred from a result of these “accidental” issues.

After that meeting, Ledford said things got better and Metro received thousands of clean loads from the company. Then came that fateful day in July, when a load of plastic, cardboard and film material came in that was inundated with an estimated 200-plus batteries throughout the load. Ledford’s team had a special place outside to sort through this material, but long story short, a fire started and events unfolded. Keep in mind that Metro was located next door to the local fire department, but even with the quick response time, the fire took off. If you look at the pictures, you can see a big mass of blue plastic with batteries, enough to power four electronic vehicles, located throughout the pile. The plastic material melted around the batteries, and it took four days, 60-plus firefighters from six to seven departments and an estimated 2 million to 3 million gallons of water to put the fire out. The worst part was that even though the material was located outside, the draft pulled the heat from the burning pile into the main building and caused all the material and equipment to light, which led to a catastrophic loss of the entire site.

Conclusion

I have always said that our nation’s waste and recycling operators are the victims of this equation. They are knowingly and unknowingly inundated with fire hazards on all sides by their customers' material. I believe manufacturers should be part of the solution, not punitively but because they are making profits from these materials and should have a “real” seat at the table, helping our nation’s waste and recycling infrastructure stay safe. In my opinion, most manufacturers deal with their suppliers in good faith and are not deliberately trying to avoid sending their materials to an e-cycler for proper disposal of their batteries, but if and when they do, whether purposefully or accidentally, I would hope they do the right thing and take responsibility for their actions.

Ryan Fogelman, JD/MBA, is vice president of strategic partnerships for Fire Rover. He is focused on bringing innovative safety solutions to market, and two of his solutions have won the distinguished Edison Innovation Award for Industrial Safety and Consumer Products. He has been compiling and publishing the “Reported Waste & Recycling Facility Fires In The US/CAN” since February 2016 and the “Waste & Recycling Facility Fires Annual Report.” Fogelman regularly speaks on the topic of the scope of fire problems facing the waste and recycling industries, early detection solutions, proper fire planning and early-stage fire risk mitigation. Additionally, Fogelman is on the National Fire Protection Association’s Technical Committee for Hazard Materials. (Connect with Ryan on LinkedIn at https://www.linkedin.com/in/ryanjayfogelman or email at [email protected])

About the Author(s)

You May Also Like