The new facility will be able to process 685,000 tons per year and will produce high-performance linerboard and corrugated medium.

Green Bay Packaging is launching a paper mill in Wisconsin that will use 100 percent recycled fiber, add mixed paper and double the capacity of its existing old corrugated paper containers (OCC) plant.

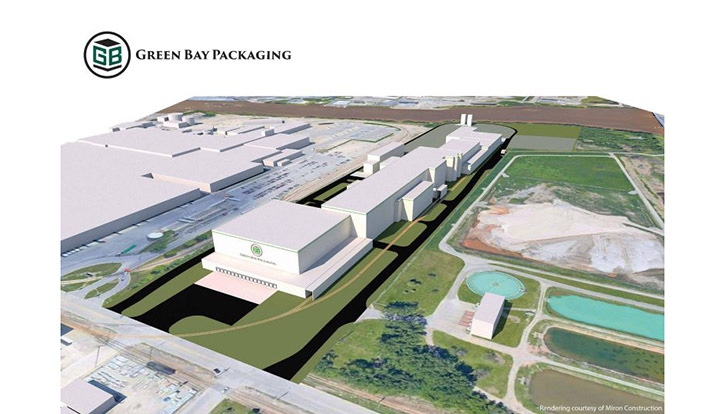

The new $500 million facility will be able to process 685,000 tons per year. End products will be high-performance linerboard and corrugated medium.

Introducing mixed residential paper while controlling for contamination adds complexity. But Green Bay Packaging has designed a robust recycling process focused on dealing with the specific challenges associated with this feedstock and with an overall drop in OCC quality, says Matt Szymanski, vice president of mill operations for Green Bay Packaging.

More cleaning and rejects handling steps have been added to ensure product performance. And the company will employ cutting-edge water management techniques as well as strength enhancement strategies to overcome reduced fiber quality associated with incorporating mixed paper fiber.

“By using state-of-the-art forming technology [to physically create a stronger sheet of paper] and size press technology [to apply strength-enhancing chemistries to products], we will be able to make a step change in product quality. This will allow performance increases in lighter-weight grades,” says Szymanski.

The company also will invest in increased paper machine trim width technology to meet the specs of customers who want wider corrugators in order to make boxes.

Modern gas boilers will replace a facility-wide coal burner, reducing sulfur dioxide and particulate matter emissions by more than 90 percent. By incorporating a reclaimed water system, it will not be necessary to draw from the Fox River, nor will the operation discharge into this natural resource. Combined green features also will cut greenhouse gas emissions by 50 percent per ton of paper.

Green Bay projects this plant will create 1,000 construction jobs and an additional 200 jobs between now and 2022. But the company’s focus on environment was at least as big a sell to the town of Green Bay.

“Green Bay Packaging’s base business is recycling, which, in and of itself, is attractive to those of us concerned about the environment. But they are going above and beyond recycling corrugate to be environmentally responsible. They are recycling water, spending a lot upfront to reduce energy costs and making other large investments to respect the environment. We appreciate that because we are community stewards as they are,” says Green Bay Mayor Jim Schmitt.

Key partners are Voith Paper, which is supplying the full packaging production line; general building contractor Miron Construction; and KSH Solutions, which will provide engineering and procurement services.

“This is the first time in United States paper history that a project with the breadth of supply and scope was delivered by a single-source company,” said Martin Jauch, president of business line projects for Voith Paper North America, in a statement. “The Green Bay project award will benefit not only the industry but also [hundreds of] dedicated workers we have in Wisconsin.”

Miron Construction mirrored that enthusiasm. “We are excited and honored to serve as the design-build partner of Green Bay Packaging. Their commitment [through this long-term investment] will benefit Green Bay, the northeast Wisconsin region and the entire state for many years to come,” said Tim Kippenhan, vice president and COO of Miron, in a statement.

While Wisconsin is the top paper manufacturer in the U.S., this will be the state’s first new mill in more than 30 years. Ongoing economic constraints, beginning around 2000, and further fueled by China’s restrictions on recycled paper, have taken hold. But Green Bay Packaging anticipates there will be demand to justify substantial upgrades, including the ability to double capacity.

Szymanski would not name customers or say where the mill would get feedstock to bump production to this level; however, he said, “The supply base is and will continue to be a mix of direct sources material and material provided by a base of brokers, primarily from Wisconsin … We will continue to grow our relationships to supply our increasing needs.”

The new mill will replace the current 70-plus-year-old plant and is expected to be fully operational by spring 2021.

Green Bay Packaging owns and runs corrugated container plants, folding cartons, recycled and virgin linerboard mills, pressure-sensitive label rollstock and specialty converting processes, among operations.

About the Author(s)

You May Also Like