The facility will feature machinery and technology from CP Group to recover recyclable commodities and prepare residual waste for further processing onsite.

San Diego-based CP Group will install an advanced material recovery facility (MRF) and front-end system for Fiberight’s new $69 million, 144,000-square-foot waste-to-energy (WTE) facility in Hampden, Maine, which is a fully functioning commercial application of Fiberight’s proprietary technology that upgrades municipal solid waste (MSW) into refined energy and industrial products.

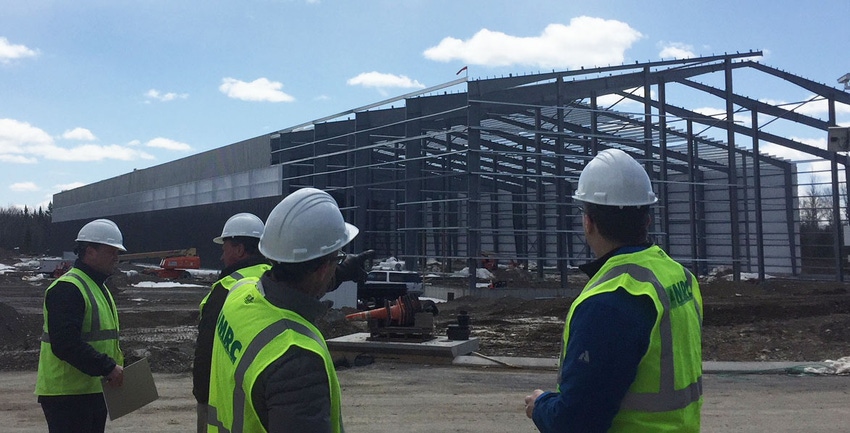

The facility is currently under construction and expected to begin receiving equipment this summer. The MRF will start up by fall 2018, and upgrading processes will be commissioned shortly thereafter.

Fiberight has been working with the Municipal Review Committee (MRC) of Maine since 2013. In February 2015, the MRC approved a development agreement with Fiberight to process 180,000 tons per year of MSW from 83 municipalities and public entities pursuant to a 15-year contract. In January 2018, Fiberight announced the completion of $70 million in project financing for the plant.

The Fiberight facility will feature the latest generation of machinery and technology from CP Group to recover recyclable commodities and prepare residual waste for further processing onsite. Fiberight anticipates landfill diversion of up to 80 percent, including recovery of metal, plastic, old corrugated cardboard and other commodities for beneficial reuse or recycling. Other commodities to be recovered include contaminated cellulose, food waste and other organic materials that may be converted into biomass, sugars, market pulp and biogas.

“We are very honored to be a part of this groundbreaking technological advancement with the Fiberight team. Their forward-thinking approach could change the way the industry processes waste, particularly fiber. We look forward to beginning installation and getting this facility into operation,” said Terry Schneider, CEO and president of CP Group, in a statement.

The Hampden facility features a CP Trommel Screen with bag-opening knives, a steel-disc CP OCCScreen, an anti-wrapping CP Auger Screen used to size material, two reduced-wrapping CPScreens for 2D/3D separation, the abrasion-resistant CP Glass Breaker to remove glass and fines and four MSS CIRRUS optical sorters. Two MSS CIRRUS PlasticMax optical sorters will recover PET and HDPE, one MSS CIRRUS FiberMax optical sorter will sort and clean fiber and one MSS CIRRUS will be used as a scavenger optical sorter to recover any remaining commodities.

“We are delighted to have teamed with CP Group to create a new paradigm for waste disposal,” said Craig Stuart Paul, CEO of Fiberight, in a statement. “Our end-to-end solution was made possible by CP’s thoughtful design process and application of the latest generation in front-end waste processing, geared specifically to our needs for downstream material upgrading.”

Fiberight’s technology is the first commercial process to convert organic wastes to biofuel and refined bioproducts. Its technology platform has been demonstrated since 2010 at its Virginia prototype production plant, using MSW feedstock. In addition to the Hampden project, Fiberight is currently involved in the development of similar projects in New England.

Paul will be speaking about Fiberight’s conversion technology at WasteExpo on Wednesday, April 25, from 1:45 p.m. to 3:00 p.m. PT in the session “A Case Study for Waste Conversion.”

About the Author(s)

You May Also Like