Anellotech’s president and CEO discusses the company’s technology for transforming plastic waste into virgin commodity chemicals for further use as raw materials.

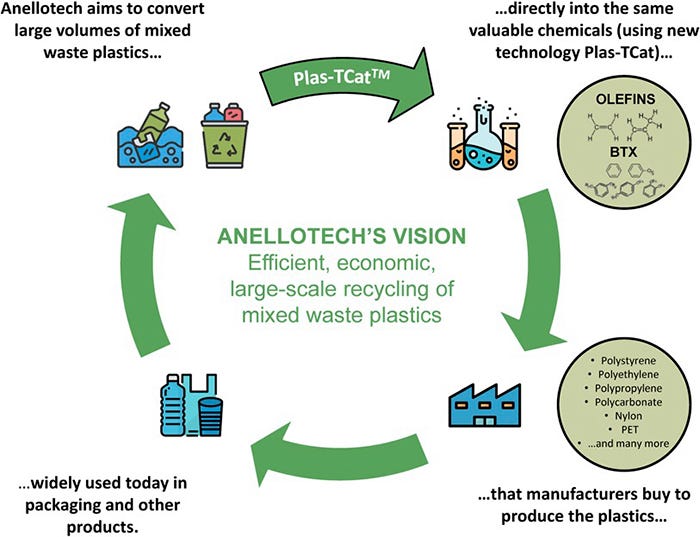

As nearly 95 percent of plastic packaging material heads to landfills or combustors annually, Anellotech Inc., a sustainable technology company based in Pearl River, N.Y., has created a new process to convert plastic waste into chemicals that can be used to make new, virgin plastics.

Plas-TCat is the thermal catalytic technology for transforming plastic waste into virgin commodity chemicals for further use as raw materials in the production of polymers in a plastics circular economy.

With Plas-TCat, single and mixed streams of plastic waste are converted into chemicals used today to produce virgin polymers used to make and package everyday products in a range of industries, such as food and beverage, textile and automotive markets.

“Anellotech is looking to use this process in areas where plastic waste collection is not yet enforced and where proper collection infrastructure to isolate waste plastics streams is currently lacking, such as developing countries in Asia that have a significant amount of ocean plastics pollution,” says David Sudolsky, president and CEO of Anellotech. “By enabling payment in waste plastic conversion to valuable chemical products, Plas-TCat can provide economic incentives to tackle plastics pollution.”

Anellotech was founded in 2008 to develop a technology platform to create more sustainable products.

“We’ve created an innovative pathway to 100 percent bio-based drop-in aromatic chemicals and fuels from non-food biomass through the development of our Bio-TCat technology,” says Sudolsky. “This unique, patented bio-based process is based on using wood as feedstock. It is the first embodiment of a broader technology platform application of thermal catalytic pyrolysis of solid materials, which also is efficient in solid waste conversion (particularly plastic waste) into commodity chemicals.”

Anellotech is planning for the design and engineering of the first Bio-TCat commercial plant, alongside its development and licensing partners IFPEN and Axens. Engineering work has begun, and the next phase of construction is targeted for the second half of 2020.

Waste360 recently sat down with Sudolsky to discuss the new Plas-TCat technology.

Waste360: What is the technology behind Plas-TCat?

David Sudolsky: Plas-TCat is a thermal catalytic pyrolysis process similar to the refining process of fluid catalytic cracking. The feedstock for the process consists of solid plastic waste. After cleaning the plastic feedstock to reduce impurities, the solid material is ground into particles that are then injected into a fluid-bed reactor in the presence of a solid catalyst.

A combination of thermal cracking, pyrolysis and catalytic reactions converts the solid materials directly into hydrocarbon products, which exit the reactor in the vapor phase. The catalyst used in the reaction is a proprietary custom formulation developed and optimized specifically for Plas-TCat.

The Plas-TCat process is an analogue of the Bio-TCat process with similar process steps and equipment configuration.

Once development work is completed, Anellotech is looking to license the process globally.

Waste360: What types of chemicals can plastics be converted into?

David Sudolsky: Once in the recycling system, waste plastics can be converted by Plas-TCat into commodity chemicals, mainly olefins (ethylene and propylene) and aromatic chemicals (benzene, toluene and xylenes), which are identical to their petro-based counterparts currently used by manufacturers to make virgin plastics.

The use of Plas-TCat is targeted to convert single and mixed plastics streams (including feeding tightly bound multi-plastics such as composite films), as well as plastics routinely found as part of the gathering and preparation steps of the plastics recycling operations.

The process is intended to be more economically attractive than competing, non-catalytic pyrolysis technologies, which produce lower-value products (pyrolysis oils, mainly waxes) as they do not use a catalyst. These pyrolysis oils require further processing in steam crackers to create some of the same valuable chemicals as Plas-TCat.

Waste360: What are the Bio-TCat lab and TCat-8 pilot systems?

David Sudolsky: Anellotech’s modern laboratory facilities are located in Pearl River, N.Y., where the basic R&D [research and development] on the Bio-TCat process has been carried out and where the Plas-TCat process is now under development. T-Cat8 is Anellotech’s pilot plant, based in Silsbee, Texas.

Over the past 30 months of on-stream pilot unit operation, Anellotech has been converting wood into product test quantities of aromatic hydrocarbons in T-Cat8, performing mass balances, confirming product yields and catalyst performance and collecting data needed for commercial scale design and improvement of operational performance.

Waste360: How do they work with Plas-TCat?

David Sudolsky: Anellotech’s laboratory reactor systems are already in use for Plas-TCat studies, and only minor modifications are required at T-Cat8 to handle plastic feedstock instead of wood.

Waste360: What studies are planned to demonstrate that the Plas-TCat process is capable of running long term?

David Sudolsky: We’ve undertaken lab studies and screened a wide variety of plastics in our laboratories to assess the potential performance in the Plas-TCat reaction environment.

Additional screening experiments are planned on a range of real-world waste plastics feedstocks—with all the impurities that come with them—to understand their impact.

This will enable us to determine the waste plastic feedstock pre-treatment requirements, design an optimum catalyst for both yield and stability and other aspects of the process. The next steps are extensive, long-term trials in the TCat-8 pilot plant with commercial feedstock.

We ran 24/7 trials for several months with our Bio-TCat program and expect to do the same thorough evaluation for Plas-TCat.

Waste360: What is the future of Plas-TCat?

David Sudolsky: We are excited about the potential of Plas-TCat, and we’re keen to seek engagement with knowledgeable strategic partners to provide development funding, as well as knowledge in waste plastics supply chain, to help accelerate this project.

About the Author(s)

You May Also Like