Companies continued to make news and product announcements at WasteExpo 2019.

WasteExpo 2019 continues to bring more news announcements from Future Industry Leaders Alliance and BDE Junior Association TOMRA SORTING RECYCLING, Eriez, PRECO, Freightliner, Fortistar and TruStar Energy, Wastequip, FleetMind Solutions Inc., ITA Dynamics, Ex-Cell Kaiser, Air-Weigh, InSight Mobile Data, Bucks Fabricating and Fairbanks Scales Inc.

Future Industry Leaders Alliance and BDE Junior Association

With a welcome reception that kicked off on Saturday and a tour of Hoover Dam on Sunday, all sponsored by SSI SCHAEFER, members of the National Waste & Recycling Association’s Future Industry Leaders Alliance (FILA) and the group’s German counterpart, BDE Junior Association (BDE J.A.), are taking advantage of WasteExpo 2019. Both groups have converged upon Las Vegas to join forces and tackle waste issues, along with giving the BDE J.A. a first-hand look at how the U.S. manages waste and recycling.

The joint group convened at Republic Services in Las Vegas to discuss topics in disruptive technologies and big data, tour the Republic Services materials recovery facility (MRF) operation and landfill and talk about family businesses.

After the morning session talking about new technologies, the team headed north to get a tour of an automation MRF demo. Once there, some up-close discussions took place regarding today’s recycling market and MRF systems. The state-of-the-art recycling facility processes up to 2 million pounds per day and services approximately 535,000 homes in and around the surrounding Las Vegas area. The recycling facility operates as a single stream facility, which saw a 400 percent increase in participation after a test of multicolored curbside bins. However, there is still a way to go on educating the public in regards to recyclables. Currently, the average contamination rate is around 30 percent, but the rate can go as high as 70 percent depending on the areas serviced.

An informational next stop proved to be an education in both waste and farming practices. With the Las Vegas strip home to global tourists on a daily basis, a bit of food waste is bound to happen. A unique method has been put in place to deal with this waste. At the base of the landfill, Republic Services partnered with Bob Combs, a pig farmer with an average of 2,000 to 2,500 pigs. It’s an unusual location, but it works. More than 25,000 tons of food waste gets heated to remove pathogens and is fed back into the food chain. The hog farm worked with Republic Services to relocate away from a previous location near the city. The hogs brought to the facility weigh roughly 60 pounds. The hogs eat around 20 pounds per day, and once the pigs weigh approximately 280 pounds, they are processed and put back into the food chain.

FILA and BDE J.A. saw other businesses working alongside Republic Services while managing waste. A local concrete and gravel company mine the landfill to create cells, which make way for waste dumping. Each year, 1.5 million tons of rock are removed in order to house the 30 tons of waste that are taken in per day. Then, there is power generation with 161 gas wells onsite. Two solar turbine engines generate enough energy to power 17,000 homes per month.

The afternoon continued with a roundtable discussion on how to navigate family business dynamics—something quite frequently seen within the waste industry. Speakers from NuWay, Lobbe, Troiano Waste and Norland gave upfront views about how family businesses morph, grow and manage while families and businesses change.

The day ended with Machinex discussing how and what to know when building a new MRF facility. Flexibility is key for a new facility. Since the future can drive different commodities, it’s best to plan for the unknown and remain flexible.

Overall, these two organizations are doing great things to help promote businesses, educate the general public and continue to drive the industry. Special thanks to SSI SCHAEFER, Republic Services and FAUN for making this event possible.

TOMRA Highlights Optical Sorter Connectivity, Increased Purity Rates

TOMRA SORTING RECYLING is unveiling information about its new cloud-based program that connects customers’ optical sorting equipment. “Show attendees visiting TOMRA booth #2241 will be among the first to learn more about how new TOMRA Insight unleashes the power of process data to transform sorting from an operational process into a strategic management tool, providing fact-based decision-making at every step of the value and production chain,” according to the company.

TOMRA Insight provides near real-time data, securely collected in the cloud, that is retrieved on desktops and mobile devices, anywhere and at any time, via a secure connection and user-friendly web interface. By providing digital metrics like throughput, material size and distribution, acceptance and rejection rates and more, TOMRA Insight gives equipment companies the operating data necessary to optimize sorting performance and reduce machine downtime.

“Our revolutionary TOMRA Insight platform unlocks the true power of data, so our customers have the necessary tools to monitor and optimize their sorting processes, improving profit potential,” said Carlos Manchado Atienza, regional director Americas for TOMRA Sorting Inc., in a statement. “Insight will allow us to enhance service and maintenance schedules, offer predictive analytics for components and develop optimal machine sorting configurations, technologies and applications.”

SHARP EYE—Deinking and Plastics

TOMRA Sorting specialists also have the latest information on the company’s SHARP EYE technology that helps recycling operations increase recovery of recyclable paper and sort single-layer PET trays from PET bottles. SHARP EYE technology features a breakthrough enhancement of its FLYING BEAM technology, expanding the sorting capabilities of the AUTOSORT machine. Featuring a larger lens for higher light intensity, SHARP EYE detects the finest molecular differences in materials flowing down the recycling line, according to the company.

The combination of TOMRA’s AUTOSORT with SHARP EYE technology allows the machine to be calibrated to identify materials suitable for deinking, making recovery rates as high as 96 percent possible in one step, added the company. For plastics recycling, operations can calibrate SHARP EYE to detect difficult-to-distinguish material properties, so it can differentiate between monolayer and multilayer PET trays from PET bottles to achieve higher and more consistent quality for new plastic food-grade packaging.

“As recovery standards become increasingly more stringent, TOMRA delivers innovative equipment and technology solutions that drive increases in material purity rates and optimize sorting efficiency,” added Atienza. “We invite all WasteExpo delegates to our exhibit to discuss their application challenges and how TOMRA’s full range of recycling solutions, including new TOMRA Insight and SHARP EYE, can help meet those needs.”

Eriez Permanent, Electric Magnetic Pulleys Transform Belt Conveyor into Self-cleaning Magnetic Separator

Permanent and Electric Magnetic Pulleys from Eriez automatically separate heavy tramp iron contaminants from conveyor transported materials. Customers can convert their belt conveyor into a powerful self-cleaning magnetic separator simply by adding an Eriez Magnetic Pulley.

Eriez Magentic Pulleys provide automatic removal of unwanted iron from materials conveyed on belts to prevent machinery damage and product contamination for sand, gravel, limestone, recycling, wood products, food, chemical, mining, rock products, ceramic, paper, plastic and rubber, coal handling and foundry operations.

All Eriez Permanent Magnet Axial Interpole Pulleys are constructed of steel center tubes with welded dividers to securely hold magnet stacks. Standard pulley models use powerful ceramic magnets in an axial interpole circuit.

Eriez Magnetic Pulleys are built to stand up to the harsh demands of severe applications involving extra-long conveyors, heavy loads or start-stop operations, noted the company. Units are finish painted, and hub bore holes are coated to prevent rust or pitting.

Eriez Magnetic Pulleys are offered in a wide range of diameters to satisfy customers’ unique needs. Larger sizes can be built to order. Options available in the Magnetic Pulley line include custom pulley face widths, shafts and lagging.

To learn more about Eriez Magnetic Pulleys, visit booth #1373.

PRECO Showcases PreView Side Defender II

In the Solid Waste Association of North America’s 2019 fatality report, the waste and recycling sectors in both the U.S. and Canada recorded 22 deaths in January alone. In 2018, more than 48 solid waste workers lost their lives, compared to the 38 lost in 2017, predominantly due to the increased incidents out on collection.

As the entire industry gathers at this year’s WasteExpo, addressing these costly and impactful safety issues is more important than ever. With experience in the safety tech industry, high product testing standards and extensive dealership network, PRECO announces it is showcasing PreView Side Defender II at booth #1667.

“With the proven blind spot and lane-change capabilities of PreView Radar systems, Side Defender II’s newly advanced technology is designed as an active on-road solution, engineered to detect vulnerable road users (VRU) while differentiating between stationary and moving objects at slow speeds,” according to PRECO. “At WasteExpo, PRECO is excited to showcase its latest innovations, including the intuitive PreView v2 in-cab display with improved audible and visual alerts, the PreView Sentry engineered for safer onsite operations and the Side Defender II with intelligent VRU awareness and lane-change assistance to mitigate incidents in urban settings.”

Freightliner's New EconicSD Features Next-level Safety Technology

The new Freightliner EconicSD, the only cabover engine refuse truck in North America that features a collision mitigation system, is on full display this year. The low-entry waste collection truck is on display in the Freightliner booth #1402 along with an array of work truck solutions for the waste industry.

The EconicSD made its North American debut at last year’s WasteExpo. The truck, which integrates safety and technology into its design inside and out, is the first Freightliner vocational truck to feature the Detroit Assurance suite of safety systems. The truck comes standard with active brake assist, adaptive cruise control and lane departure warning technologies.

This truck also comes standard with Side Guard Assist, a feature on refuse routes, which uses two radar sensors to monitor the proximity of the truck’s passenger side for objects such as traffic signs, bicyclists, vehicles, etc. Additionally, the EconicSD features a rain/light sensor, which automatically activates headlights and wipers. The vehicle also features the optional Blind Spot View, consisting of multiple video cameras, making the driver more visually aware of their immediate surroundings and operating environment.

Spec’d with the Detroit DD8 mid-range engine with Detroit Connect Virtual Technician remote diagnostic service, the EconicSD aims to maximize uptime for refuse fleets.

The EconicSD’s low step-in height and spacious, ergonomic cab were designed with driver comfort in mind. An automated frame lowering feature further reduces the already low step-in height for easy entry and egress. Modern features such as a panoramic windshield, a 90-degree door opening and an aggressive wheel cut for enhanced maneuverability further contribute to the driver-focused design of the EconicSD, according to the company.

“The EconicSD and its technology-forward, modern design has been incredibly well received by waste collection customers since we unveiled this vehicle at the 2018 WasteExpo,” said Richard Saward, general manager of vocational and government vehicle sales for Freightliner Trucks, in a statement. “Leveraging the global prowess of Daimler, we are proud to offer a game-changing vehicle that brings next-level safety and innovation to the refuse industry—and to the neighborhood and community streets where safety matters the most.”

Also featured in the Freightliner booth are the Freightliner M2 106 vehicles with a wide selection of body configurations including side loaders, roll-off hoists and grapple bodies.

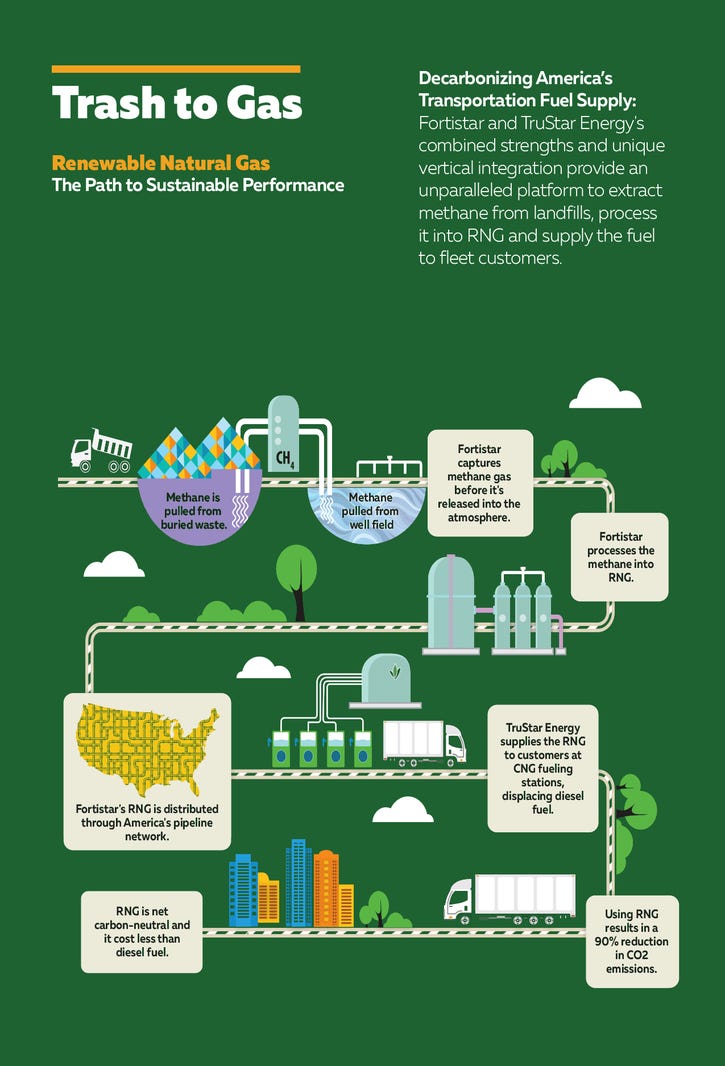

Fortistar, TruStar Energy Accelerate Plan to Decarbonize Transportation Fuel Via RNG

Fortistar and TruStar Energy, two of the nation’s leaders in renewable natural gas (RNG) production and compressed natural gas (CNG) fuel supply, will discuss RNG with landfill owners, project developers and fleet owners during WasteExpo at booth #2308.

With the recently announced acquisition of Beacon Energy Facilities in Pennsylvania, Fortistar is now extracting methane from landfills and converting it to RNG, paving the way for a sustainable transportation fuel supply chain working with its affiliate, TruStar Energy.

“RNG offers a tremendous opportunity to decarbonize America’s transportation fuel supply,” said Mark Comora, president of Fortistar and chairman of TruStar Energy, in a statement. “Our firm has operated in dozens of landfill gas-to-energy projects; TruStar Energy has constructed 250 natural gas fueling stations. We are closing the RNG supply loop as a uniquely vertically integrated company, extracting it from landfills and moving it into natural gas trucks. We are looking forward to speaking with industry and municipal representatives at WasteExpo to accelerate this opportunity.”

“Natural gas as a transportation fuel has proven to be a great success story for fleets—both economically and environmentally—and the communities they serve with quieter trucks and cleaner air,” said Adam Comora, CEO of TruStar Energy, in a statement. “TruStar Energy is extremely proud of our role in that success story. As we look into 2019 and beyond, we are excited to build on that success by expanding our RNG offerings, which drive economic benefits and drastically reduce the carbon as compared to diesel fuel.”

For more than 25 years, Fortistar has built, invested in and managed portfolios of successful independent power and clean energy generation projects in both the United States and in Canada. If you are a landfill owner, operator, project developer or fleet owner/operator, Fortistar and TruStar Energy are interested in meeting with you during WasteExpo.

Wastequip Debuts Rectangular Roll-off Container with Removable Sign

Wastequip is launching a new line of rectangular roll-off containers featuring patent-pending large removable sign plates during WasteExpo. These new containers were designed to address growing hauler demand for more professional-looking and easy-to-maintain branded equipment offerings.

The new roll-off container with removable signage and several other exciting new products will be on display at Wastequip booth #523.

The new roll-off container models with removable sign plates offer a large, flat, recessed metal surface to accommodate a graphic of up to 70 inches wide by 35 inches high. The recessed signage area is protected by an L-shaped frame that securely holds the sign against the reinforced container sidewall. The L-shaped frame is designed to shed water and prevent rust and corrosion.

Featuring bullet hinges, a rust-resistant zinc chain, a pivoting angle frame to clamp the sign in place on all four edges, a rotating pipe presses and locks the free end of frame. The container allows for graphic installation and/or replacement. To swap out graphics, operators need only to pull the handle toward them. The frame swings open from right to left, allowing them to slide a new metal sign plate into place and close the frame, using the handle to lock it down securely in place against the container.

There are three sign plate options available: aluminum, steel or a customer-provided replacement panel. Customers also may continue to have decals installed directly on the container between the cross-members. All removable sign options are lightweight enough to allow easy installation by one person.

“Wastequip is committed to working closely with haulers to anticipate and deliver on their needs,” said Kirk Warren, director of product management for Wastequip steel products, in a statement. “Working closely with haulers every day, we understand their desire to better promote their company by ensuring their equipment is well maintained and consistently branded. These new roll-off containers will help them easily maintain a consistent, branded appearance for their entire roll-off container fleet, enhancing customer loyalty and preference.”

FleetMind, ITA Dynamics Release Fully Integrated Financial, Route Management System

FleetMind Solutions Inc. and ITA Dynamics have integrated their two products in order to provide North American waste management and recycling companies with a seamlessly integrated “all-in-one” solution for billing, route management and service verification.

FleetMind and Microsoft partner ITA Dynamics are showcasing their integrated solution for route management and financial controls at WasteExpo booths #1973 and #4264, respectively.

Using FleetMind’s FleetLink Route System and ITA Dynamics’ Microsoft Dynamics 365 Business Central ENWIS products together, solid waste fleets can create customers, assign subscriptions, dispatch routes and handle on-demand stops, all while maintaining a single version of events. They also can leverage FleetLink Reports’ extensive service verification capabilities, which provide time-stamped, location-based photographic evidence of service delivery, to provide proof from within Microsoft Dynamics ENWIS to rapidly resolve customer service queries, particularly complaints about missed service or excessive billing.

“We believe that by working together with ITA Dynamics, an innovator in solid waste billing, we will provide haulers with a solution that delivers meaningful productivity gains and unique new business insight,” said Don Diego Padilla II, vice president of sales for FleetMind, in a statement. “Automatic real-time integration between our two solutions means that vehicles on the road have immediate access to new customers as well as on-demand stops, while back office systems have immediate access to the data required to drive customer conversations as well as revenue recognition.”

“We are very excited that ITA Dynamics is able to fulfill our mission of creating ‘One Version of the Truth’ by integrating our Microsoft Dynamics ENWIS financial and waste solution with FleetMind’s FleetLink suite of applications,” said Michael Ayoroa, president and CEO of ITA Dynamics, in a statement. “By ensuring that our Microsoft Dynamics ENWIS (ENterprise Waste Information Software) financial application, specifically designed for the needs of the waste and recycling community, can populate FleetLink Route System in real time, we are delivering on our goal of maintaining a reliable, single source of truth for all waste management operations.”

With FleetLink Route System, FleetLink has developed a complete solution for creating, managing and dispatching routes for solid waste and recycling haulers. With WasteApp and FleetLink Reports, FleetMind has developed a complete solution for service verification. FleetLink Route System, FleetLink Reports and WasteApp are all part of the FleetLink suite of applications, which, in addition to route management, offer vehicle tracking, reporting, video recording and playback and a safety dashboard.

ENWIS is a complete enterprise resource productivity system that can be hosted both on premise or in the Microsoft Azure cloud.

Ex-Cell Kaiser: Say YES to Steel and NO to Plastic

Making small changes in your everyday life can make a huge difference in your environmental footprint. Switching from plastic straws to steel, silicone or paper straws can save thousands of pounds of single-use plastic over a lifetime. It’s estimated that in just one day, more than 250 million straws are used in the United States.

Ex-Cell Kaiser, a manufacturer and designer of decorative steel waste and recycling receptacles, is giving WasteExpo 2019 attendees a free set of reusable stainless-steel straws. Stop by booth #4358 and pick up your free set of stainless-steel drinking straws (available while supplies last).

Janet Kaiser, owner and CEO of Ex-Cell Kaiser Manufacturing & Design, said this is just one small part of the company’s commitment to sustainability and the environment.

“Since 1933, all Ex-Cell Kaiser waste and recycling receptacles have been sustainably made in the USA, are 100 percent steel and stainless steel and contribute to closed loop recycling efforts,” said Kaiser in a statement. “Unlike plastic, which can only be recycled once or twice before heading to a landfill, the metals used by Ex-Cell Kaiser can be recycled an infinite number of times.”

“Each and every day, we’re looking for new ways to leave a positive environmental footprint. Whether through our own day-to-day business operations, our products and manufacturing process or the messages we convey, we’re committed to protecting the environment and natural resources,” she added.

Air-Weigh Onboard Scales, InSight Mobile Data Announce Integration Option

Eugene, Ore.-based Air-Weigh, the global electronic onboard scales provider, is teaming up with InSight Mobile Data to provide a seamless fleet management solution for the refuse market, allowing for users to view in-route bin weights through communication with InSight’s StreetEagle fleet management software.

Both Air-Weigh and InSight Mobile Data are showcasing their latest integration options at WasteExpo in booths #1328 and #4190, respectively.

“This project was born from the needs of a mutual customer, and working with InSight during the discovery phase has been a pleasure,” said Jim Janke, integration specialist at Air-Weigh, in a statement. “Our customer was already getting valuable weight data from our BinMaxx Front End Loader scale, and now with integration with StreetEagle, that data is sent instantly to the back office, optimizing decision-making.”

With a focus on efficiency for fleets, this integration brings the ability to access container content weight for individual commercial containers, pickup location and detailed customer information along with real-time tracking for routing, alerts, GPS location and more to any smart device or computer. The user can view, manage and export valuable data from anywhere.

"With the combined technologies of StreetEagle and Air-Weigh, users can create zones on our maps for their customers and know accurate bin weights, number of bins collected, service intervals and the expected weight range per bin,” said Chris Eller, director of product development for InSight, in a statement. “They can measure whether each customer's bin weights are light, expected or excessive, and that's key intelligence that many of these operations do without right now. But with this solution, these companies can get a much more precise picture on what they're spending per customer and make smarter business decisions from there. We're excited to provide waste operations with this level of insight."

Here are the companies’ latest integration options on display:

BinMaxx Scale from Air-Weigh: A weigh-in-motion scale with arm-mounted sensors that weigh every lift. With sensors on the vehicle’s arms, there is greater advantage in functionality, durability and cost over other fork-mounted scales, according to the company.

StreetEagle Software from InSight Mobile Data: Instant insight into every resource, at any time, on any device, featuring real-time tracking, mapping, instant alerts and comprehensive reporting, stated the company.

Bucks Fabricating Relaunches Tough Box

After receiving multiple requests for a light-duty roll-off container, Bucks Fabricating has decided to give its customers what they want.

“We are relaunching our light-duty roll-off, now known as the Tough Box,” announced Bucks Fabricating. “With industry standard features, the Tough Box is ideal for trash pickup, recycling debris, light demolition and other light-duty work. Along with this relaunch, we have a new name for our product line, The Work Force. The Work Force comes complete with the Tough Box, Strong Box and Ultra Box, being able to serve a variety of industries from trash pickup, to construction, to heavy-duty scrap.”

According to the company, The Strong Box is a well-known and popular medium-duty container, previously known as the Contractor Duty. For those heavy-duty scrappers, Bucks said it will continue to manufacture its heavy-duty container with the new title of the Ultra Box.

Unsure of which container is right for your business? Bucks’ sales team is available to help at booth #4059.

Fairbanks Scales Showcases Latest in Vehicle Weighing Innovations

Fairbanks Scales Inc., the oldest scale company in the U.S. and a leader in weighing equipment, is showcasing a wealth of state-of-the-art industrial scales at WasteExpo booth #4464. Fairbanks Scales’ latest innovations in weighing equipment on display include a large-scale model of the new lift-deck truck scale for waste operations equipped with Intalogix lightning/power surge protection system.

The Fairbanks Heavy Capacity Lift Deck Truck Scale is a new scale for transfer station scales. According to Fairbanks, the “easy-to-clean solution is the ideal choice for shallow pit scale replacement or new transfer station scale construction projects.” The scale’s decks can be quickly and easily lifted and removed with lightweight equipment to hose out debris or dirt that accumulates, keeping the scale running smooth and accurate even in the harshest environments, added the company.

In addition, the Lift Deck Truck Scale is equipped with the proprietary Intalogix lightning protection system. Designed and developed by Fairbanks, this state-of-the-art technology has a true digital signal, which protects the scale from any harmful surges or electrical spikes, noted the company.

Also on display is the FB6015 instrument, which includes the features and functionality refuse companies need for their transfer station operation. “In addition, the rugged and durable 1605RF Remove Display, which is a critical component to the transfer station operation to maximize the loading of each transfer truck, will also be featured,” added Fairbanks.

Have WasteExpo 2019 news to share? Email Waste360 Editorial Director Mallory Szczepanski at [email protected].

About the Author(s)

You May Also Like