Roughly 200 billion packages are shipped globally every year, and that figure is on the rise as ecommerce booms. Now a subcategory of this business model is emerging: “recommerce” or reverse commerce where products and or packaging can be returned for reuse.

Petaluma, Calif.-based Boox is riding the wave of this early trend, providing reusable exterior shipping boxes to replace traditional cardboard boxes, and reusable bags to replace single-use poly bags or padded mailers. Launched in the throes of COVID, the young company shipped 100,000 reusable packages in 2021 and is on track to ship one million more in 2022.

One million a year is a drop in the bucket, admits Boox CEO and co-founder Matt Semmelhack. But he’s encouraged as the company is starting to see brands—mainly in “clean beauty,” outdoor, fashion, and apparel spaces—as well consumers embracing the concept.

“A lot of brands don’t have brick and mortar stores [shelving products with minimal to no packaging].

So, their customers’ first interaction with the product is with the box or bag that’s delivered to their doorstep. It’s important to send the right message at that moment. For brands, increasingly that message is: ‘We are sustainable.’ And a great way to send that message is through the package it’s shipped in,” Semmelhack says.

Part of the sustainable packaging piece is designing for reuse; part of it is minimizing material in the first place.

Boox supplies reusable shippers to brands’ fulfillment centers where they are packed then shipped. Customers scan a QR code on their mobile phones for guidance on how to return to locations available through Boox’s partnership with Happy Returns, who offers a large network of drop-off sites to multiple brands. The QR code also provides data on when it is returned, and tracks return rate by brand.

Once packages make it back to Boox, they are refurbished, sanitized, then put back into circulation for reuse.

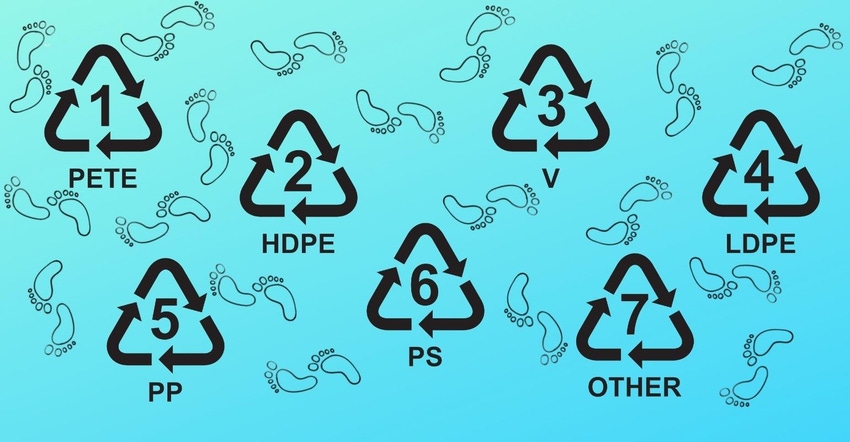

Going back to not-so-long-ago, Semmelhack says, “When we got started, we thought we would find a durable box and ship in it, but this proved to not be that easy. My colleague, Paige Russell, and I ended up designing a Boox Box [made of durable polypropylene with 20-25% of it recycled content]. But we needed more than a box. We had to figure out a system to easily return it.”

On the design front the box, which is the first product, had to be lightweight, affordable, and protective of the merchandise inside. On the return system side, the process had to be manageable and convenient for consumers.

Still, neither designing the package nor figuring out a return system were the toughest challenges. What has been hardest is changing consumer behavior. This reverse logistics model is still a new concept. Some people have not fully understood how it works. And or they saw returning the packaging as less convenient than simply putting it out for curbside pickup.

Being able to tap into Happy Return’s large infrastructure has been key to adoption. Ninety percent of the customers of Boox’s U.S. clients are within 10 minutes of a drop off. In urban areas they are closer, with the drop-off points growing, according to Semmelhack.

Boox continues to spend a lot of time on messaging and education to try and bring more consumers on board, explaining why and how to use the system.

“We are finding simple incentives increase participation rate, return, and reuse while also helping to gain new customers and helping with retention. So, we encourage brands to incentivize customers, offering discounts on new purchases when they return boxes,” Semmelhack says.

The company just introduced reusable, returnable Boox Baags made of 95% recycled polyester and recycled nylon, a cheaper alternative to boxes. The early customers are in the garment industry, while the first primary takers of the boxes are cosmetic companies whose products are often in glass or have otherwise fragile components needing more durable outer packaging. But Boox is targeting other sustainably- minded ecommerce brands.

The company began in the U.S. and recently launched in the U.K. with a similar reverse logistics system. European customers take packages to lockers and scan the QR code; the locker opens; and they place the packaging inside.

Semmelhack anticipates adoption will be easier in Europe where curbside recycling is less common. People are accustomed to taking recyclables to drop offs so doing the same with reusables will not be so different.

The Boox Box allows retailers to cut down their environmental impact of traditional cardboard by 70% or more after 10 shipments, according to a third-party lifecycle analysis (depending on variables such as box types). Only internal testing has been done on the newer offering, Boox Baags, which shows they can be reused hundreds of times. Shipping is cheaper than with the boxes, with the boxes within 3-5% of the cost for branded cardboard boxes.

Now the team is working to develop other reuse options.

“We are finding ways to extend that reuse concept beyond shipping our boxes and bags, to the products themselves and their primary packaging. For example, we’re working with a wine subscription company to provide a Boox Box that it can ship wine in, but also enabling its customers to return the box with empty wine bottles in them. So, the box and wine bottles themselves can be reused,” Semmelhack says.

Plans for 2023 are to expand into Canada, where there is now a wait list of clients asking to sign up, though the reverse logistics network still needs to be developed. While reusable package designs are starting to become a little more common, infrastructure to move them along generally lags further behind.

There’s more work ahead in other areas. The team is trying to figure out an efficient refurbishing process, which will likely also entail educating consumers, and even shippers, on how to handle packaging. Boxes need to be pristine, but some come back written on, run over by delivery trucks, or otherwise damaged, and dealing with this has been labor intensive.

REN Skincare is the first fairly sizable client in the beauty and wellness space. The company ships about 60,000 Boox Boxes in a year.

“Switching to Boox required minimal operational changes from our end. We fulfill orders as normal, but in reusable Boox Boxes instead of single-use packaging. Boox takes care of the reverse logistics process and keeps us stocked up with boxes as needed,” says AJ Patel, Global head of E-Commerce at REN Skincare.

Among the company’s other sustainability work, it uses aluminum/glass jar packaging and recycled ocean waste plastic and has replaced sachet samples with a 100% recycled aluminum tube.

“REN takes a holistic approach to sustainability. Our zero-waste pledge [to design packaging to be recyclable, containing recycled materials, or as reusable] was met at the end of 2021, and the journey continues.

This will include a renewed commitment to packaging alternatives … with new brands and pledges, mindfully sourcing more sustainable ingredients, as well as looking at direct-to-consumer shipping and ecommerce that helps reduce waste through reusable packaging,” Patel says.

Currently, Boox is running pilots with what Semmelhack describes as big, well-known brands.

“When other companies see these popular household names doing it, we believe [recommerce] will not just be what ecowarriors do, but it will become how shipping is done. We believe this will be the beginning of a domino effect.”

About the Author(s)

You May Also Like