What Landfill Operators Should Know About Methane Oxidation

Reducing methane emissions is a front and center priority for landfills, whether through gas collection systems or other means – including methane oxidation, which occurs in landfill cover soils when bacteria in the soil consume the gas. Researchers point to methane oxidation through covers as a key strategy for emissions mitigation, but only fairly recently have landfill operators become aware of the potential impact of this management strategy and how they can leverage it to their advantage.

“When you talk about methane oxidation in covers, one main issue that was happening is no one knew how to quantify it,” says Tarek Abichou, professor at Florida A&M University-Florida State University (FSU) College of Engineering.

With no means to accurately gauge, the U.S. Environmental Protection Agency (EPA) defaulted to a 10% methane oxidation rate (operators could report a 10% reduction in emissions to account for methane oxidation in cover soils). But emerging research would show that oxidation can vary from 10 to 35%. Among influencers of oxidation capacity were soil cover type and flux (rate that methane travels through the cover). This gained knowledge led to EPA’s reconsideration of oxidation potential, which motivated some operators to think about how they can boost this natural process and ultimately cut greenhouse gas emissions.

Ray Huff, vice president at SCS Engineers, explains the relevance of flux and ties in the role of landfill covers.

“The evaluation of flux is important to determine how much methane is coming out of the surface. Now, with emerging research, EPA allows operators to calculate methane oxidation rates based on flux. And you can determine flux based on cover type, as well as surface area.” This is important he says because looking at flux and applying different oxidation rates enables a more realistic estimate of actual emissions and gives operators context so they can adjust how they manage landfill operations.

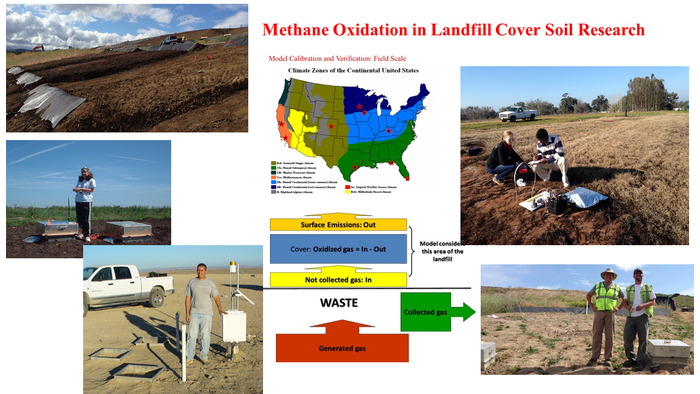

Abichou and his colleague Jeff Chanton, professor of Environmental Science at FSU, were at the forefront of the research to determine how to gauge methane oxidation.

In their work they looked at two isotopes before, and then after, methane entered the soil cover: carbon 13 and carbon 12. They learned that after methane goes through the cover there was more carbon 13 than carbon 12.

“By that shift in the ratio of carbon 13 to carbon 12 you can tell how much methane the bacteria ate, and ultimately how much oxidation occurs,” says Abichou.

They also discovered that percent of oxidation depends on flux and that the lower the flux the higher the oxidation rate because gas stays in the cover longer.

With more science to go by, EPA has pivoted from a one-size-fits-all default value and integrated in its federal regulations consideration of the amount of gas that goes through the cover, as well as factors such as landfill condition and climate.

“When EPA would only acknowledge that landfill owners were achieving 10 percent oxidation a lot of them were not really considering methane oxidation as a viable way to reduce emissions. Once they saw there was a way to document more than 10 percent, they wanted to know, how can I get to 35 percent? How do I invest to make my cover achieve this?” says Abichou.

A common measurement tool is flux chambers that are placed on the landfill surface to monitor changing concentrations over time. By monitoring flux occurring in the chamber operators can estimate the actual flux.

Methane oxidation is dependent on several specific conditions, with one being the availability of pores for the gas to pass through. More porosity equates to greater availability of oxygen to facilitate oxidation. With that said, sand or gravel covers are more effective than clay or silt, explains Pat Sullivan, senior vice president at SCS Engineers.

But another parameter is residence time, or how long the methane remains in the cover.

“If a cover material is too porous there is not enough residence time for oxidation. So, you need an optimal combination of soil type plus cover thickness. The thicker the cover the more time methane will spend in it to optimize methane oxidation,” says Sullivan.

Though he cautions that too many thick layers can be problematic; for instance, they can impede the landfill gas collection system.

Some operators have looked at specialty layers, such as finished compost or shredded green waste that can enhance oxidation potential and provide additional emission benefits. In California Sullivan has seen biocovers like these used very effectively, though he notes there has been a move away from this option, except in some cases where emissions have been especially problematic, as it is thought that the materials should be reserved for other beneficial uses.

The function of the cover and gas collection system go hand in hand, notes Chanton, pointing out that once methane generation has dropped off to a certain level the gas collection system can be deactivated and methane oxidation in the cover can manage what gas remains. He and Abichou developed a prediction tool to calculate oxidation capacity and help determine when the cover can sufficiently manage remaining gas.

Abichou believes methane oxidation and the ability to calculate it can have applications beyond the current ones – that measurement methodology could provide data to help operators obtain carbon credit offsets.

“Before the market crash in late 2007 we actually started to work on how to include methane oxidation into the carbon credit marketplace. We’re still talking about that.

We are working specifically on developing a tool to help finance the closing of open dumps in third-world countries. It would take the determined reduction and convert to carbon credits. I think that’s where methane oxidation needs to go … to be used as a natural process to safely close open dumps, and carbon credits could help finance this.”

About the Author

You May Also Like