OnePlus sensors and monitors are wireless devices that, through the use of the Internet of Things (IoT) waste monitoring solutions, measure the fullness level of many different types of waste and recyclable containers.

For years, grocery retailer Kroger Corp., based in Cincinnati, Ohio, has challenged its family of supermarket brands to participate in its corporate-wide sustainability initiative.

In 2009, King Soopers, a Kroger brand chain of supermarkets with 150 locations across Colorado and Wyoming, approached OnePlus Systems, a Northbrook, Ill.-based manufacturer of container fullness and control systems, to improve the chain’s waste management processes.

“At the time, many King Soopers locations contracted haulers to service their compactors on a fixed schedule,” says Brendan Walsh, president of OnePlus Systems. “The problem with scheduled hauls is that the chances of a compactor being just full when the hauler arrives are slim. This means that unnecessary hauls were occurring, trucks were on the road when they need not be, and there was always a risk of over-filling compactors.”

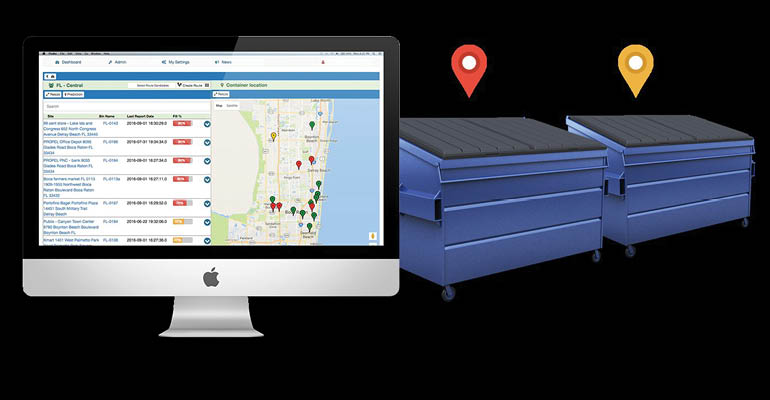

Today, one-third of King Soopers locations use OnePlus monitoring. OnePlus sensors and monitors are wireless devices that, through the use of the Internet of Things (IoT) waste monitoring solutions, measure the fullness level of many different types of waste and recyclable containers, including compactors, trade waste bins and liquid tanks. Using ultrasonic and pressure sensing techniques, the sensors primarily measure fullness levels, in addition to container tracking and container service events.

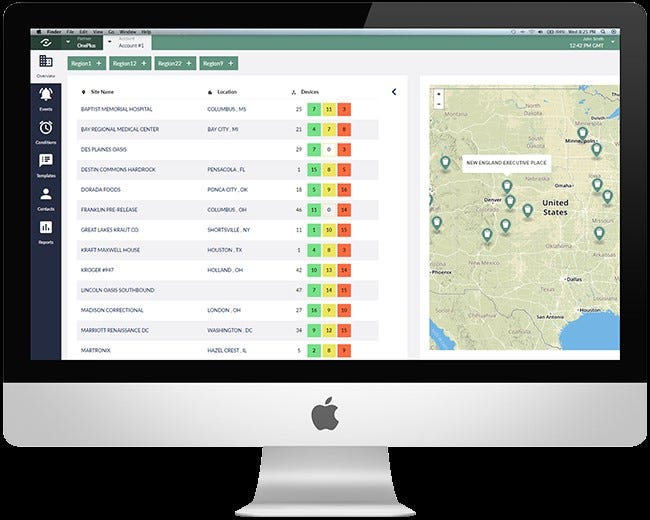

On the analytics side, the WasteForce platform and mobile applications offered by OnePlus Systems provide a control center view of waste operations. Users, like King Soopers, can login to WasteForce to see real-time fill-levels of all their containers or compactors.

“Cost savings per location averaged about 15 to 20 percent,” says Ralph Powell, manager reclamation for King Soopers in Denver, Colo. “Financial justification of the purchase required about 2 years of savings to cover the equipment charge and monitoring fees.”

According to Powell, King Soopers approached OnePlus to improve the supermarket’s waste flow management process and ensure full loads were being hauled less frequently, which would save trash hauling costs.

“The trash hauler is notified by OnePlus when the compactor PSI reaches a level deemed proper for having a full load within legal weight limits of the specific area,” he says. “Service time given to the hauler from notification has been set at 24 hours. Volume adjustments with seasonal and holiday concerns can be made easily with this system.”

The OnePlus Fullness Monitor was the best fit for King Soopers, according to Walsh. Positioned close to an on-site compactor, the fullness monitor uses pressure sensing and cellular networks, just like a cell phone, to report accurate fullness levels to the WasteForce platform.

“This enabled store managers to always know their available capacity and central management to see the current status for each of the locations remotely,” says Walsh. “One of the best features of the solution is the direct communication between WasteForce and the contracted hauler.”

When a compactor has reached its ideal fullness level, the hauler is contacted automatically to notify them that now is the right time to service.

“With the right solution in place, unnecessary hauls have been eliminated, a significant cost has been reduced, and King Soopers has valuable waste data to incorporate in to their sustainability program,” says Walsh.

This year marks OnePlus Systems’ 25th year of providing waste monitoring solutions.

“In fact, long before the ‘Internet of Things’ expression was coined, OnePlus Systems was monitoring thousands of compactors across North America. We're proud of that,” says Walsh.

In June 2016, OnePlus acquired a provider of intelligent waste monitoring solutions for non-compacting containers, SmartBin.

“For over two decades OnePlus were the only name in IoT compactor monitoring. It was time to diversify and address the rest of the waste market,” says Walsh. “Smart monitoring of non-compacting containers was still a relatively new industry with few players. However, one company clearly stood out, Dublin-based SmartBin.”

In contrast to OnePlus, SmartBin sensors used ultrasonic sensing and both cellular and IoT networks to communicate.

“Now, whether our clients use compactors, front end loaders, tanks, or any other waste or recycling container, we have an end-to-end solution to address their business needs,” says Walsh. “And no matter which container types or how many, our clients can access everything in one place. This is something no other company in the world can provide.”

About the Author(s)

You May Also Like